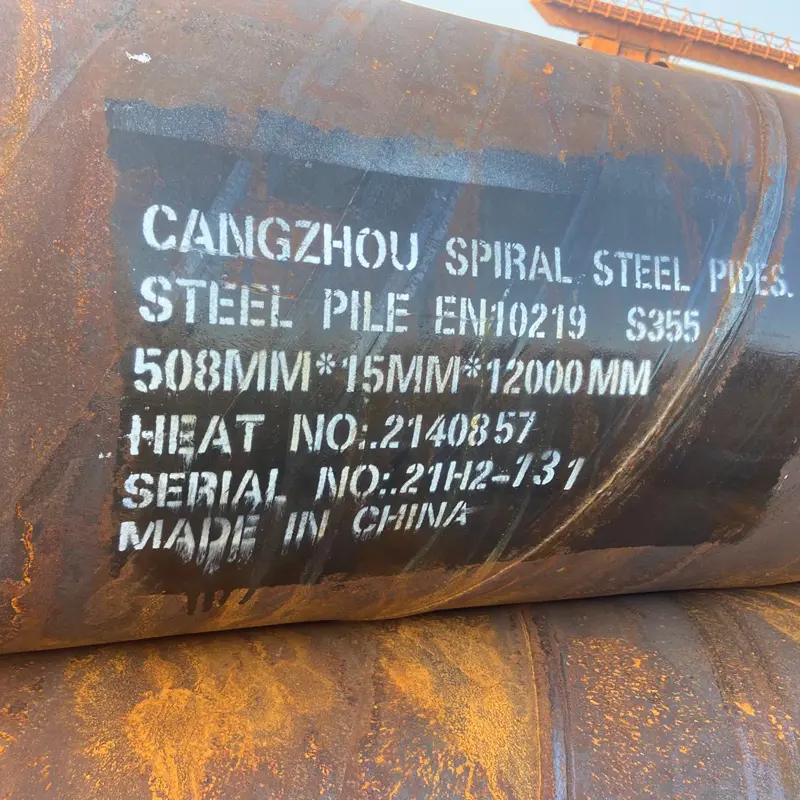

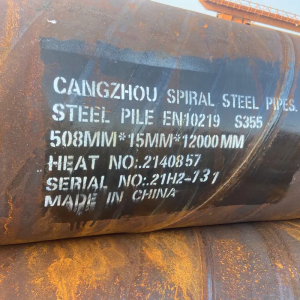

S355 J0 Spiral Seam Welded Pipe For Sale

We are pleased to introduce to you our latest product, S355 J0 Spiral Steel Pipe, which is a spiral seam welded pipe made of high-quality strip steel coil as raw material. Our spiral seam welded pipes are manufactured using an advanced automatic twin-wire double-sided submerged arc welding process.

Mechanical Property

| steel grade | minimum yield strength | Tensile strength | Minimum elongation | Minimum impact energy | ||||

| Mpa | % | J | ||||||

| Specified thickness | Specified thickness | Specified thickness | at test temperature of | |||||

| mm | mm | mm | ||||||

| <16 | >16≤40 | <3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

The S355 J0 Spiral Steel Tube is constructed with precision and excellence ensuring durability and reliability in its performance. It is a low-alloy high-strength structural steel plate, widely used in machinery manufacturing, heavy industry machinery, construction machinery, mining machinery, coal mining machinery, bridge structures, cranes, generators, wind power equipment, bearings and other industries. Shells, pressure components, steam turbines, embedded parts, mechanical parts.

One of the main features of the S355 J0 Spiral Steel Tube is its versatility. Spiral steel pipes are widely used and can meet various needs of different industries. Whether it's heavy machinery or infrastructure projects, this pipe offers exceptional performance and strength, making it ideal for demanding applications.

Chemical Composition

| Steel grade | Type of de-oxidation a | % by mass, maximum | ||||||

| Steel name | Steel number | C | C | Si | Mn | P | S | Nb |

| S235JRH | 1.0039 | FF | 0,17 | — | 1,40 | 0,040 | 0,040 | 0.009 |

| S275J0H | 1.0149 | FF | 0,20 | — | 1,50 | 0,035 | 0,035 | 0,009 |

| S275J2H | 1.0138 | FF | 0,20 | — | 1,50 | 0,030 | 0,030 | — |

| S355J0H | 1.0547 | FF | 0,22 | 0,55 | 1,60 | 0,035 | 0,035 | 0,009 |

| S355J2H | 1.0576 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| S355K2H | 1.0512 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| a. The deoxidation method is designated as follows: | ||||||||

| FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al). | ||||||||

| b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. | ||||||||

At Cangzhou Spiral Steel Pipe Group Co., Ltd., we pride ourselves on our state-of-the-art manufacturing capabilities. With 13 production lines of spiral steel pipes, and 4 production lines of anti-corrosion and thermal insulation measures, we have become a leading supplier in the industry. Our advanced production technology enables us to produce spiral steel pipes with a diameter of Φ219-Φ3500mm and a wall thickness of 6-25.4mm.

We are committed to providing high quality products that meet the highest industry standards. Our team of skilled professionals ensures that each pipe undergoes rigorous quality inspections for strength, durability and performance. Moreover, we prioritize customer satisfaction and provide excellent after-sales service to our valued customers.

With our S355 J0 Spiral Steel Pipe, you can rely on the superior quality and reliability that our brand stands for. Whether you are in the heavy machinery or construction industry, our spiral steel pipes will exceed your expectations and deliver outstanding results.

Choose Cangzhou Spiral Steel Pipe Group Co., Ltd. for all your spiral steel pipe needs. Partner with us today and experience the unparalleled quality and reliability of our products.

Hydrostatic Test

Each length of pipe shall be tested by the manufacturer to a hydrostatic pressure that will produce in the pipe wall a stress of not less than 60% of the specified minimum yield strength at room temperature. The pressure shall be determined by the following equation:

P=2St/D

Permissible Variations In Weights and Dimensions

Each length of pipe shall be weighed separately and its weight shall not vary more than 10% over or 5.5% under its theoretical weight, calculated using its length and its weight per unit length

The outside diameter shall not vary more than ±1% from the specified nominal outside diameter

Wall thickness at any point shall not more than 12.5% under the specified wall thickness