PIPE COATING AND LINING

-

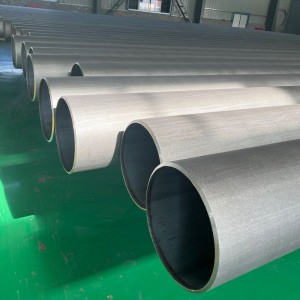

Spiral Submerged Arc Welding Of Polyethylene Lined Pipes

Introducing our revolutionary polypropylene lined pipe, the ultimate solution for underground water pipe systems. Our polypropylene lined pipes are manufactured using advanced spiral submerged arc welding technology, ensuring superior quality and durability. This state-of-the-art pipe is designed to meet the highest standards for groundwater supplies, providing a reliable and long-lasting solution for a variety of applications.

-

Outside 3LPE Coating DIN 30670 Inside FBE Coating

This standard specifies requirements for factory-applied three-layer extruded polyethylene-based coatings and one or multi-layered sintered polyethylene-based coatings for the corrosion protection of steel pipes and fittings.

-

Fusion-Bonded Epoxy Coatings Awwa C213 Standard

Fusion-Bonded Epoxy Coatings and Linings for Steel Water Pipe and Fittings

This is an American Water Works Association(AWWA) standard. FBE coatings is mainly used on steel water pipes and fittings, for example the SSAW pipes, ERW pipes, LSAW pipes seamless pipes, elbows, tees, reducers etc. for the purpose of corrosion protection.

Fusion-bonded epoxy coatings are one part dry-powder thermosetting coatings that, when heat activated, produce a chemical reaction to the steel pipe surface while maintaining the performance of its properties. Since 1960 on, application have expanded to larger pipe sizes as internal and external coatings for gas, oil, water and wastewater applications.