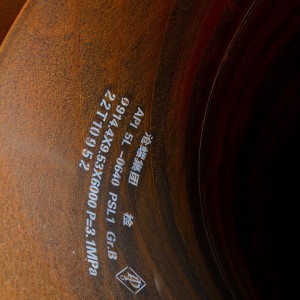

Versatile Spiral Welded Steel Pipes

Spiral welded steel pipes are specially designed to meet the diverse needs of different industries and are widely used in oil and gas transportation, tube pile construction, bridge piers and other fields. Its unique structure and excellent performance make it the first choice of traditional pipe materials, with unique advantages that enhance its functionality and efficiency.

One of the main advantages of spiral welded steel pipe is its cost-effectiveness. Compared to seamless steel pipes, welded steel pipes are cheaper to produce without compromising quality. This makes operations more economical, making it ideal for projects requiring large quantities of steel pipe for a variety of applications. By reducing costs, companies can allocate resources more efficiently, resulting in significant savings on the overall project budget.

Mechanical Property

| Grade 1 | Grade 2 | Grade 3 | |

| Yield Point or yield strength, min, Mpa(PSI) | 205(30 000) | 240(35 000) | 310(45 000) |

| Tensile strength, min, Mpa(PSI) | 345(50 000) | 415(60 000) | 455(66 0000) |

In addition, the production efficiency of spiral steel pipes is significantly higher than that of seamless steel pipes. For seamless pipe, the production process involves extruding a solid steel billet through a perforated rod, resulting in a relatively slower and more complex production process. In contrast, spiral welded pipe can be manufactured in larger diameters and lengths, resulting in shorter production times and increased efficiency. This ensures a consistent supply of high-quality pipes in shorter time periods, making it a reliable and time-saving solution for various industries.

Another noteworthy advantage of spiral welded pipes is their excellent resistance to external pressure and mechanical stress. Welds provide additional durability, allowing these pipes to withstand higher pressures than seamless pipes. This property is particularly important for applications in the oil and gas industry, where pipelines are subject to significant internal and external pressures. By using spiral welded pipes, companies can ensure the safe and efficient transportation of these important resources.

In addition, the versatility of spiral welded pipe makes it highly adaptable to various construction requirements. These pipes can be customized to meet specific project needs, including varying diameters, thicknesses and lengths. Whether for pipe pile installations or bridge piers, spiral welded steel pipes provide excellent solutions for both onshore and offshore applications. Its superior structural integrity ensures long-lasting performance, reduces maintenance costs and minimizes the need for premature replacement.

In short, spiral welded pipe is bringing a revolution to the steel pipe industry with its excellent performance and significant advantages. Its superior cost-effectiveness, higher production efficiency, pressure resistance and adaptability to numerous applications make it the first choice in oil and gas transportation, pipe pile construction, bridge piers and more. With its seamless surface and welded seams, this innovative product provides a reliable and durable solution to industries around the world. Invest in spiral welded pipe and experience cutting-edge advancements in steel pipe technology.