Spiral Seam Welded Pipe GBT9711 2011PSL2

We are pleased to introduce our newest product, spiral seam welded pipe. This innovative multi-functional product is made by rolling low-carbon carbon structural steel or low-alloy structural steel strips into tube blanks at a certain spiral angle, and then welding the tube seams. This unique manufacturing process allows us to produce large diameter steel pipes from relatively narrow strips.

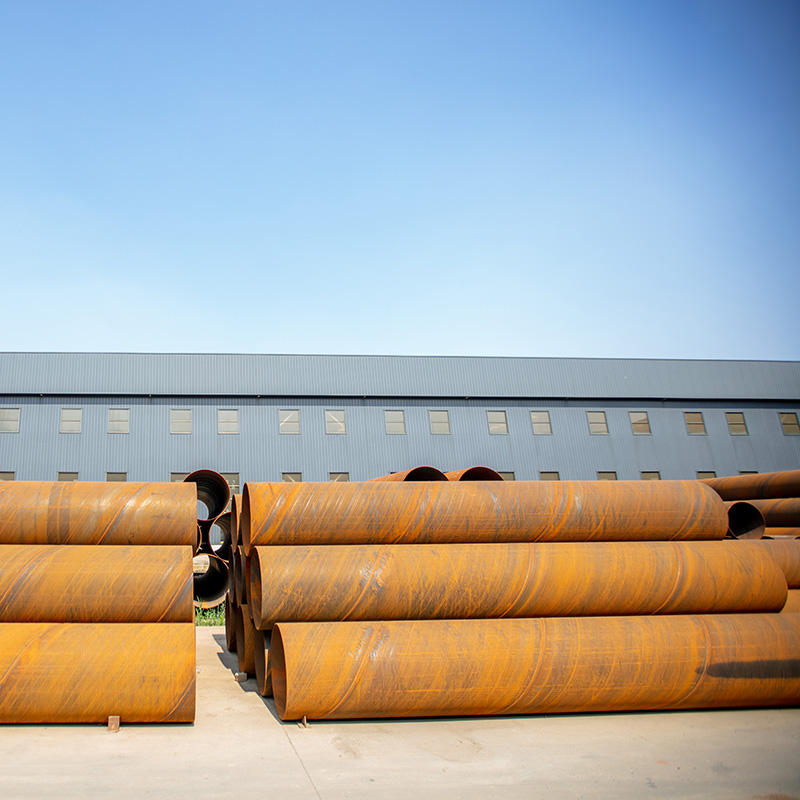

At Cangzhou Spiral Steel Pipes Group Co., Ltd., we take great pride in our state-of-the-art facilities and cutting-edge technology. Covering an area of 350,000 square meters and with total assets of 680 million yuan, it has become a leader in the industry. With a dedicated team of 680 employees, through unremitting efforts, the company has an annual output of 400,000 tons of spiral steel pipes and an output value of 1.8 billion yuan.

| Standard |

Steel grade |

(%)Chemical composition | Tensile properties | Charpy ImpactTest and DropWeight Tear Test | ||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Other | CEV4)(%) | Rt0.5 MpaYield strength |

Rm Mpa Tensile Strength |

Rt0.5/ Rm | (L0=5.65 √ S0 ) Elongation A% | |||||

| max | max | max | max | max | max | max | max | max | min | max | min | max | max | min | ||||

|

GB/T9711 -2011 (PSL2) |

L245MB | 0.22 | 0.45 | 1.20 | 0.025 | 0.15 | 0.05 | 0.05 | 0.04 | 1) | 0.40 | 245 | 450 | 415 |

760 |

0.93 |

22 | Charpy impact test: Impactabsorbingenergy of pipe body and weld seam shall

be tested as required in the original standard. For details, see the original standard. Drop weight tear test: Optional shearing area |

| L290MB | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 1) | 0.40 | 290 | 495 | 415 | 21 | ||||

| L320MB | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 1) | 0.41 | 320 | 500 | 430 | 21 | ||||

| L360MB | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 1) | 0.41 | 360 | 530 | 460 | 20 | |||||||

| L390MB | 0.22 | 0.45 | 1.40 | 0.025 | 0.15 | 1) | 0.41 | 390 | 545 | 490 | 20 | |||||||

| L415MB | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 1)2)3 | 0.42 | 415 | 565 | 520 | 18 | |||||||

| L450MB | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 1)2)3 | 0.43 | 450 | 600 | 535 | 18 | |||||||

| L485MB | 0.12 | 0.45 | 1.7 | 0.025 | 0.015 | 1)2)3 | 0.43 | 485 | 635 | 570 | 18 | |||||||

| L555MB | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 1)2)3 | 协议Negotiation | 555 | 705 | 625 | 825 | 0.95 | 18 | |||||

| Note:1)0.015 ≤ Altot < 0.060;N ≤ 0.012;AI—N ≥ 2—1;Cu ≤ 0.25;Ni ≤ 0.30;Cr ≤ 0.30;Mo ≤ 0.10 | ||||||||||||||||||

| 2)V+Nb+Ti ≤ 0.015%3)For all steel grades, Mo may ≤ 0.35%, under a contract.

Mn Cr+Mo+V Cu+Ni 4)CEV=C+ 6 + 5 + 5

|

||||||||||||||||||

One of the key advantages of our spiral seam welded pipe is its unparalleled strength and durability. The use of high-quality steel strips ensures that our pipes can withstand extreme conditions and heavy loads, making them suitable for a wide range of applications. From oil and gas transmission to water and sewer systems, our pipes guarantee reliable performance and long-lasting service.

Additionally, our spiral seam welded pipes offer exceptional versatility. With the ability to produce large diameter steel pipes, we can meet a variety of project requirements and specifications. Whether you need pipes for infrastructure development, construction projects or industrial applications, we have the capabilities to meet your needs.

In addition to strength and versatility, our spiral seam welded pipes offer excellent corrosion resistance. This is critical, especially in industries that are frequently exposed to harsh environments and corrosive substances. Our pipes are engineered to stand the test of time, ensuring optimal performance even in the most demanding conditions.

At Cangzhou Spiral Steel Pipes Group Co., Ltd., we are committed to providing quality products and excellent customer service. Our strict quality control measures and stringent testing procedures ensure that every spiral seam welded pipe leaving the factory meets the highest industry standards. Additionally, our dedicated customer support team is here to help with any questions or concerns you may have.

All in all, our spiral seam welded pipes are a reliable and efficient solution for a variety of applications. Through our state-of-the-art manufacturing processes and commitment to excellence, we have become a trusted supplier in the industry. Whether you are looking for strength, versatility or corrosion resistance, our spiral seam welded pipe is the ideal choice. Choose Cangzhou Spiral Steel Pipes Group Co., Ltd. for all your steel pipe needs.