Versatility Of Spiral Welded Pipe In Oil And Gas Pipes

One of the main advantages of spiral welded pipe is their ability to withstand high pressures. This makes them ideal for transporting oil and gas over long distances. The spiral welding process creates a strong, seamless pipe that can handle extreme conditions without compromising its structural integrity. This is critical to the oil and gas industry, as the transportation of these precious resources requires reliable and durable pipelines.

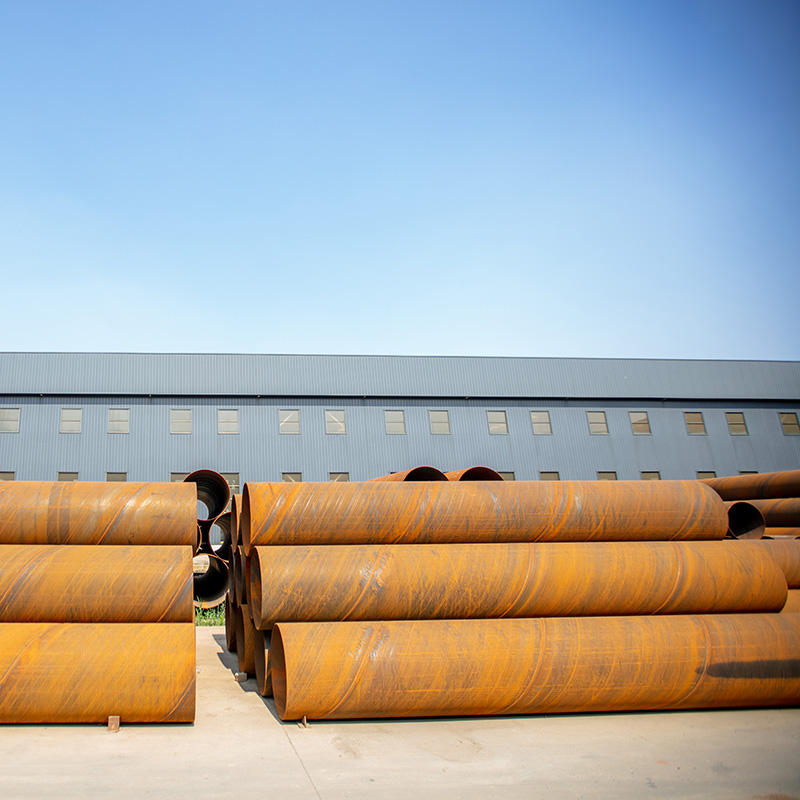

In addition, spiral welded pipe is highly resistant to corrosion, making it a cost-effective choice for oil and gas pipes. The welding technology used in its construction results in a smooth, uniform surface that is less susceptible to rust and other forms of corrosion. This means that spiral welded pipe has a longer service life than other types of pipe, reducing the need for frequent maintenance and replacement.

In addition, the versatility of spiral welded pipe is reflected in its flexibility in design and construction. These pipes can be manufactured in a variety of sizes and thicknesses, making them suitable for a variety of plumbing applications. Their flexibility also makes installation easier, especially in challenging terrain or environments. Whether it is an onshore or offshore project, spiral welded pipe provides the adaptability needed to meet the specific requirements of oil and gas line pipes.

Another significant advantage of spiral welded pipe is its cost-effectiveness. The manufacturing process of these pipes is more efficient compared to other types of pipes, thus reducing production costs. Additionally, their corrosion resistance and longer service life mean reduced maintenance and replacement costs. This makes spiral welded pipe a cost-effective choice for oil and gas pipe projects, ultimately contributing to overall project savings.

In conclusion, the versatility of spiral welded pipe in oil and gas pipes is undeniable. Their strength, corrosion resistance, design flexibility and cost-effectiveness make them the first choice for many pipeline projects. As demand for oil and natural gas continues to grow, spiral welded pipe will continue to play a vital role in the safe and efficient transportation of these precious resources. With its many advantages, it’s no wonder that spiral welded pipe is the first choice in the oil and gas industry.

All in all, our spiral seam welded pipes are a reliable and efficient solution for a variety of applications. Through our state-of-the-art manufacturing processes and commitment to excellence, we have become a trusted supplier in the industry. Whether you are looking for strength, versatility or corrosion resistance, our spiral seam welded pipe is the ideal choice. Choose Cangzhou Spiral Steel Pipes Group Co., Ltd. for all your steel pipe needs.