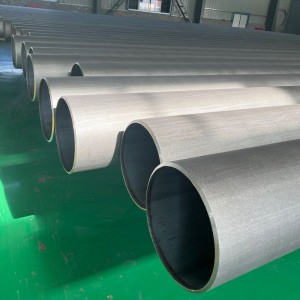

Spiral Welded Carbon Steels Pipe For Water Line Tubing

1. Understand spiral welded carbon steel pipe:

Spiral welded carbon steel pipe is spirally formed and welded from steel coils. The unique manufacturing process makes these pipes stronger and more durable, able to withstand high internal and external pressures. The ability to resist corrosion and deformation also makes it suitable for a wide range of applications, including water pipes and metal pipe welding.

|

Standard |

Steel grade |

Chemical composition |

Tensile properties |

Charpy Impact Test and Drop Weight Tear Test |

||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | CEV4)(%) | Rt0.5 Mpa Yield strength | Rm Mpa Tensile Strength | Rt0.5/ Rm | (L0=5.65 √ S0 )Elongation A% | ||||||

| max | max | max | max | max | max | max | max | Other | max | min | max | min | max | max | min | |||

| L245MB |

0.22 |

0.45 |

1.2 |

0.025 |

0.15 |

0.05 |

0.05 |

0.04 |

1) |

0.4 |

245 |

450 |

415 |

760 |

0.93 |

22 |

Charpy impact test: Impact absorbing energy of pipe body and weld seam shall be tested as required in the original standard. For details, see the original standard. Drop weight tear test: Optional shearing area |

|

|

GB/T9711-2011(PSL2) |

L290MB |

0.22 |

0.45 |

1.3 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

1) |

0.4 |

290 |

495 |

415 |

21 |

|||

| L320MB |

0.22 |

0.45 |

1.3 |

0.025 |

0.015 |

0.05 |

0.05 |

0.04 |

1) |

0.41 |

320 |

500 |

430 |

21 |

||||

| L360MB |

0.22 |

0.45 |

1.4 |

0.025 |

0.015 |

1) |

0.41 |

360 |

530 |

460 |

20 |

|||||||

| L390MB |

0.22 |

0.45 |

1.4 |

0.025 |

0.15 |

1) |

0.41 |

390 |

545 |

490 |

20 |

|||||||

| L415MB |

0.12 |

0.45 |

1.6 |

0.025 |

0.015 |

1)2)3 |

0.42 |

415 |

565 |

520 |

18 |

|||||||

| L450MB |

0.12 |

0.45 |

1.6 |

0.025 |

0.015 |

1)2)3 |

0.43 |

450 |

600 |

535 |

18 |

|||||||

| L485MB |

0.12 |

0.45 |

1.7 |

0.025 |

0.015 |

1)2)3 |

0.43 |

485 |

635 |

570 |

18 |

|||||||

| L555MB |

0.12 |

0.45 |

1.85 |

0.025 |

0.015 |

1)2)3 | Negotiation |

555 |

705 |

625 |

825 |

0.95 |

18 |

|||||

| Note: | ||||||||||||||||||

| 1)0.015 ≤ Altot < 0.060;N ≤ 0.012;AI—N ≥ 2—1;Cu ≤ 0.25;Ni ≤ 0.30;Cr ≤ 0.30;Mo ≤ 0.10 | ||||||||||||||||||

| 2)V+Nb+Ti ≤ 0.015% | ||||||||||||||||||

| 3)For all steel grades, Mo may ≤ 0.35%, under a contract. | ||||||||||||||||||

| Mn Cr+Mo+V Cu+Ni 4)CEV=C+ 6 + 5 + 5 | ||||||||||||||||||

2. Water line tubing:

In water distribution systems, the safe and efficient delivery of clean water is critical. Spiral welded carbon steel pipe has proven to be a reliable choice for water pipes due to its corrosion-resistant properties. The smooth surface of these pipes minimizes friction, ensuring a constant flow of water and reducing turbulence. Additionally, inherent strength and durability guarantee protection against leaks, breaks, and structural failures, ensuring a continued, reliable water supply.

3. Metal pipe welding:

The welding industry relies heavily on spiral welded carbon steel pipe for a variety of applications. The exceptional strength and flexibility of these pipes make them ideal for metal pipe welding. Whether building large storage tanks, pipelines to transport oil and gas, or structural components in industrial settings, spiral welded carbon steel pipes play a vital role. The uniformity of welded joints ensures the reliability and safety of the structure, reducing the need for frequent maintenance or repairs.

4. Benefits and advantages:

4.1 Cost-effective solution: Spiral welded carbon steel pipe provides a cost-effective solution for water pipe and metal pipe welding. Their durability and corrosion resistance ensure a longer service life, thus reducing replacement and maintenance costs.

4.2 Easy to install: The spiral welding technology used in the manufacturing process can produce longer and continuous pipes, reducing the need for frequent joints. This streamlined design simplifies the installation process, saving time and effort.

4.3 Versatility: Spiral welded carbon steel pipes are available in a variety of diameters and thicknesses, allowing them to be adapted to different applications. They can be customized to meet specific project requirements, adapting to a variety of fluids, pressures and temperatures.

4.4 Environmental protection: Carbon steel is a recyclable material that contributes to environmental sustainability. Spiral welded carbon steel pipes can be recycled and reused, reducing waste and protecting natural resources.

In conclusion:

The capabilities and advantages of spiral welded carbon steel pipes in water pipe and metal pipe welding cannot be underestimated. The efficient and reliable transfer of water and industrial fluids relies heavily on their durability, corrosion resistance and ease of installation. As the need for strong and cost-effective infrastructure continues to rise, spiral welded carbon steel pipes will remain a critical component in ensuring the smooth operation of water systems and industrial processes around the world.