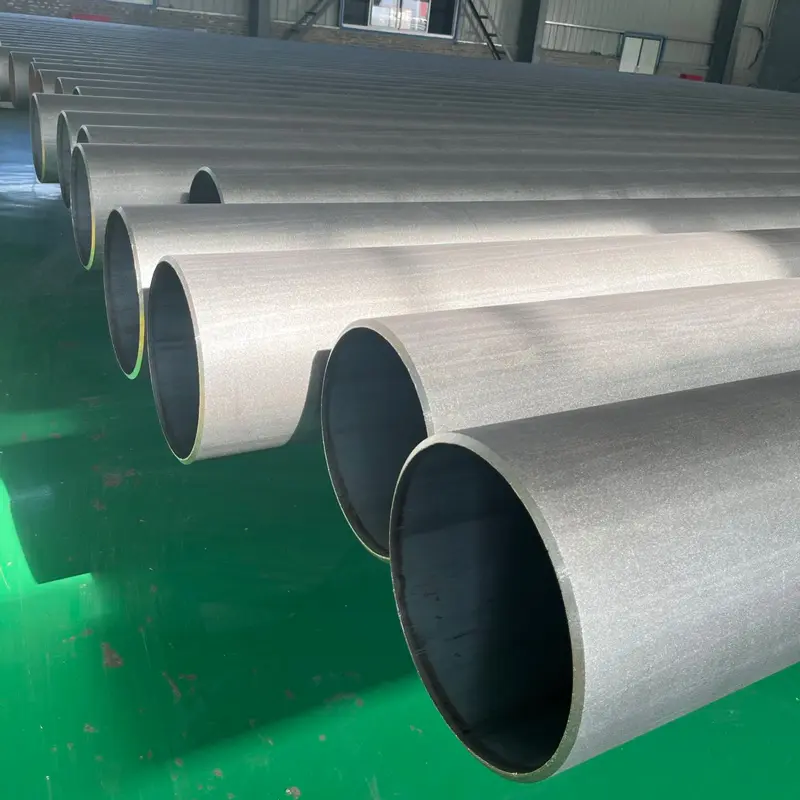

Spiral welded pipe is an important component in various industries including oil and gas, construction and water infrastructure. The pipes are manufactured using a special process called spiral welding, which involves joining strips of steel to create a continuous spiral shape. This production method offers many advantages, including high strength, durability and cost-effectiveness. In addition, spiral welded pipes comply with international standards such as EN10219 to ensure their quality and performance.

EN10219 is a European standard that specifies the technical delivery conditions for cold-formed welded structural hollow sections of non-alloy steel and fine-grained steel. This standard outlines requirements for the manufacturing process, material properties and dimensional tolerances of spirally welded steel pipes to ensure their suitability for structural applications.

The production of spiral welded steel pipes first selects high-quality steel coils, and then uncoils and feeds them into the spiral welding machine. The machine uses a continuous welding process to join the edges of the steel strip, creating a spiral seam along the length of the pipe. The welds are then subjected to non-destructive testing to ensure their integrity and strength. After welding, the pipes undergo various finishing processes, including sizing, straightening and inspection, to meet the requirements of EN10219.

One of the main advantages of spiral welded steel pipe is its ability to withstand high internal and external pressures, making it suitable for transporting fluids and gases in various industries. Additionally, the spiral welding process can produce pipes in a variety of diameters and thicknesses, providing design and construction flexibility. These pipes are also resistant to corrosion, which further improves their longevity and performance in demanding environments.

Compliance with EN10219 is essential to ensure the quality and reliability of spiral welded steel pipes. The standard imposes strict requirements on material composition, mechanical properties and dimensional tolerances to ensure that pipes meet the performance standards required for structural applications.

In addition, EN10219 also specifies the testing and certification procedures that manufacturers must comply with, including non-destructive testing of welds, mechanical performance testing and visual inspections. By adhering to these strict standards, manufacturers can provide customers with a quality and performance guarantee of spiral welded steel pipe.

In summary, the production and standards for spiral welded steel pipes outlined in EN10219 play a vital role in ensuring the reliability and performance of these important components. By utilizing the spiral welding process and adhering to strict manufacturing standards, manufacturers can produce high-quality pipe that meets the needs of various industries. As a result, EN10219 becomes a valuable framework for the production, testing and certification of spiral welded steel pipes, contributing to their widespread use in critical infrastructure and construction projects around the world.

Post time: Jan-31-2024