Introduce:

In the vast area of industrial infrastructure, the importance of efficient and reliable piping systems cannot be underestimated. Traditional piping often suffers from corrosion, leaks and insufficient strength. However, a revolutionary solution has emerged that can effectively solve these problems – the spiral seam tube. In this blog, we take a deep dive into the world of helical seam pipes, exploring their unique benefits, applications, and their impact on improving efficiency and reliability across industries.

Advantages of spiral seam pipe:

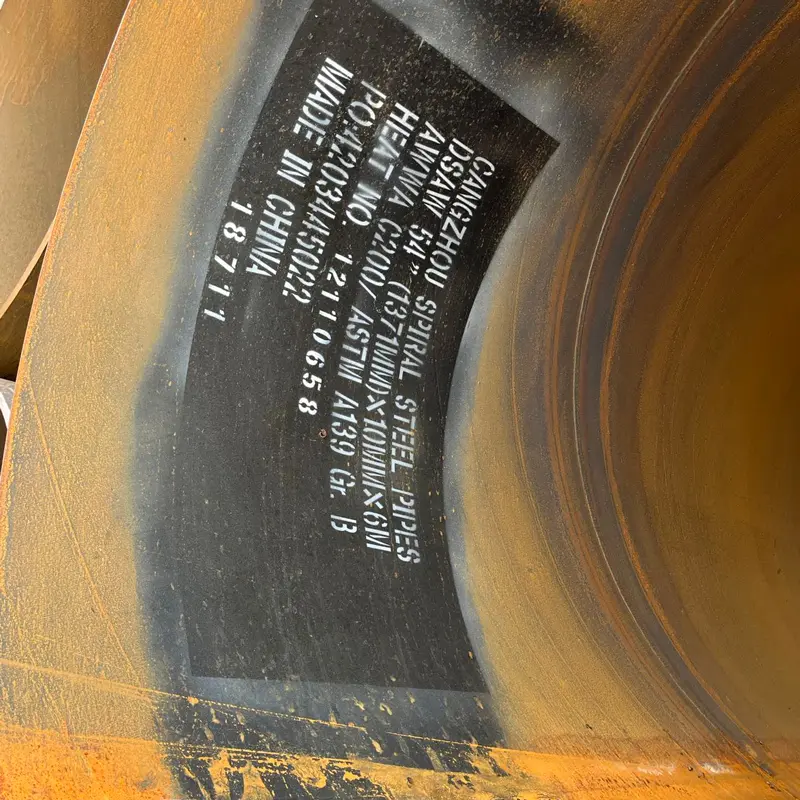

Spiral seam tubing derives its strength and durability from its unique manufacturing process. These pipes are formed by continuously winding a steel strip around a mandrel, with helical seams. This unique design has many advantages that make spiral seam tubing very popular in industrial applications.

1. Enhanced strength and durability:

The spiral seam design of these pipes ensures exceptional strength and durability, making them suitable for extreme pressure and heavy loads. This makes them ideal for offshore platforms, refineries and other challenging environments.

2. Corrosion resistance:

Corrosion is a major problem for pipelines. However, helical seam pipe is made from materials that have excellent corrosion resistance, preventing rust and other forms of degradation. As a result, they last longer than conventional pipes, reducing the need for frequent maintenance or replacement.

3. No leakage performance:

One of the greatest advantages of spiral seam tubing is its welded seams, which allow for a seamless, leak-free solution. By eliminating the risk of leaks, these pipes provide a reliable means of fluid transfer, ensuring the safety and efficiency of industrial processes.

Application of spiral seam pipe:

Spiral seam pipe has wide applicability in various industries due to its robustness and reliability. Some key applications include:

1. Oil and gas industry:

In the oil and gas sector, spiral seam pipes are used to transport hydrocarbons over long distances. The pipeline’s ability to withstand high pressure and corrosive environments makes it an integral part of offshore drilling, refinery and power distribution networks.

2. Water supply system:

Spiral seam pipe is also well suited for water supply systems where corrosion and leak resistance are critical. Whether for municipal water supplies or irrigation networks, these pipes ensure the efficient and reliable distribution of clean water.

3. Infrastructure construction:

In infrastructure projects, spiral seam pipe is widely used in drainage, stormwater management and underground utility systems. Its solid construction and excellent resistance to external elements make it a trusted choice for large-scale construction projects around the world.

In conclusion:

Spiral seam tubing offers an innovative solution that increases efficiency and reliability across industries. From exceptional strength and corrosion resistance to leak-free performance, these pipes demonstrate reliability in even the most challenging environments. Their widespread use in the oil and gas industry, water supply systems, and infrastructure development proves their effectiveness. Employing these exceptional tubing can significantly reduce maintenance costs while increasing safety and productivity. As the industry continues to evolve, spiral seam tubing will undoubtedly play a key role in shaping a more resilient and efficient future.

Post time: Aug-29-2023