Introduce:

When selecting the appropriate lining material for a sewer pipe, decision makers are often confronted with multiple options. Commonly used materials are polypropylene, polyurethane and epoxy. Each of these materials brings a unique character to the table. In this article, we’ll take an in-depth look at the features and benefits of polypropylene lined pipes, polyurethane lined pipes, and epoxy sewer liners to help you make an informed choice.

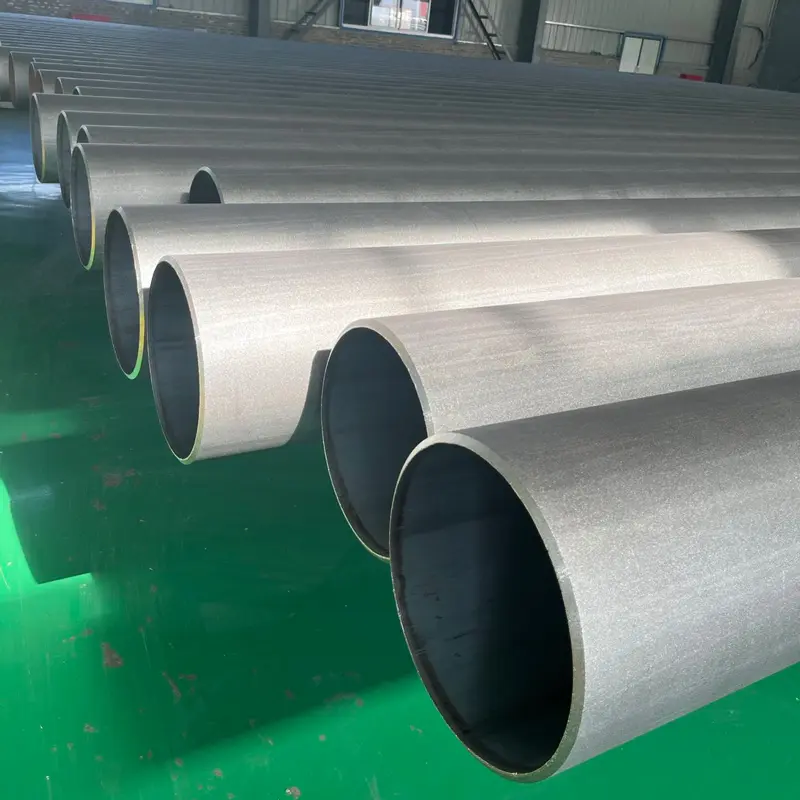

Polypropylene liner:

Polypropylene lined pipe is a popular choice for sewer applications due to its excellent chemical resistance. Polypropylene is a thermoplastic polymer that imparts excellent chemical resistance to the lining material. This type of lining is ideal for installations conveying corrosive fluids or where high wear resistance is required. Polypropylene lined pipe is lightweight, making it easier to transport and install. Additionally, they have low friction for efficient fluid flow and reduced energy consumption.

Polyurethane Lined Pipe:

Polyurethane lined pipe is incredibly resistant to abrasion, impact and abrasion. This makes it an excellent choice for sewer systems subject to abrasive substances or high flow rates. The polyurethane liner provides a smooth, durable layer of protection that reduces the chance of sediment buildup that can cause clogged pipes. Additionally, polyurethane is known for its flexibility, able to withstand frequent ground movement and temperature fluctuations without cracking or cracking.

Epoxy sewer liner:

Epoxy sewer pipe lining is popular for their ability to repair aging infrastructure without expensive excavation. Epoxy liner forms a tough, corrosion-resistant barrier to prevent leaks, root intrusion and deterioration. This method ensures a smooth interior finish and enhances the flow capacity of the sewer system while greatly extending its service life. Additionally, epoxy sewer liners are cost-effective, time-saving and environmentally friendly, making them an advantageous choice for municipalities and facility managers looking for sustainable solutions.

Comparative analysis:

To better understand the differences between the three lining materials, we compare them based on key parameters:

1. Chemical resistance:

Polypropylene-lined pipe excels in this regard, offering excellent resistance to a wide range of aggressive chemicals. Polyurethane-lined pipes are also well-resistant, but their chemical resistance is relatively low. Epoxy sewer liners offer excellent chemical resistance.

2. Wear resistance:

Polyurethane lined pipe has excellent abrasion resistance, making it ideal for sewer applications subject to abrasion. Polypropylene lined pipes offer moderate resistance, while epoxy sewer liners are not specifically designed to withstand severe wear and tear.

3. Installation flexibility:

Polypropylene lined pipe offers flexibility during installation due to its lightweight composition. Polyurethane-lined pipes are moderately flexible, while epoxy sewer liners are more rigid and require precise application techniques.

In conclusion:

Selecting the proper lining material for sewer lines is critical to maximizing the efficiency, longevity and cost-effectiveness of the system. While each material offers unique benefits, the final choice depends on the specific requirements of your sewer system. Polypropylene lined pipes offer excellent chemical resistance, polyurethane lined pipes provide excellent abrasion resistance, and epoxy sewer liners work wonders for restoration projects. Understanding the benefits and limitations of each material enables decision makers to make informed choices to ensure the longevity and optimal performance of sewer systems.

Post time: Aug-22-2023