Enhanced Corrosion Resistance Fbe Coated Pipe

Introducing our enhanced corrosion resistant FBE coated pipe, a cutting-edge solution designed to meet the rigorous demands of modern infrastructure. Engineered to the highest industry standards, our products are specifically designed to provide superior corrosion protection for steel pipe and fittings. Our FBE coated pipe features an advanced factory-applied three-layer extruded polyethylene coating and one or more layers of sintered polyethylene coating, ensuring long-lasting durability and reliability in even the most challenging environments.

Enhanced corrosion resistant FBE coated pipes are suitable for a variety of applications including oil and gas, water supply and industrial projects. Its superior coating technology provides a strong barrier against corrosion, ensuring the longevity and integrity of the pipe system. With our commitment to quality and innovation, you can be confident that our FBE coated pipes will stand the test of time, reduce maintenance costs and improve operational efficiency.

Product Specification

Main Feature

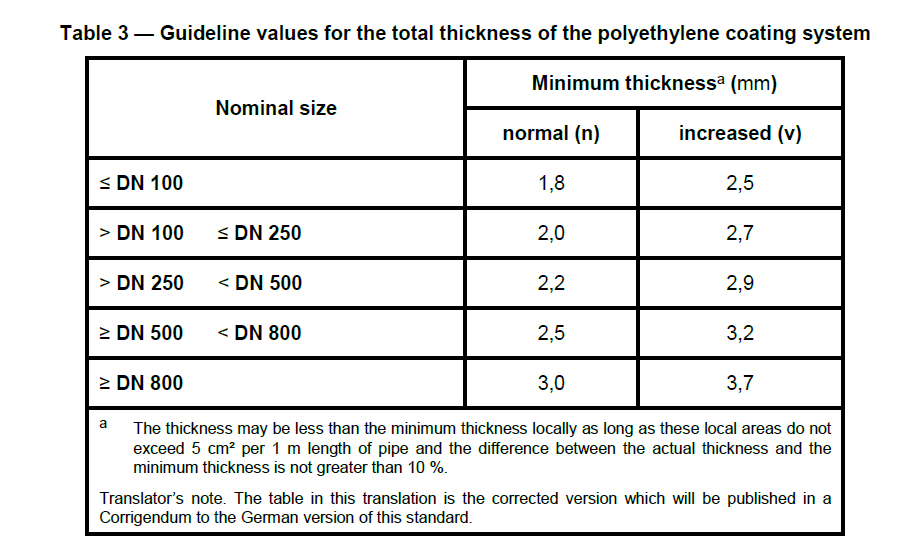

FBE coated pipe is designed with three layers of extruded polyethylene coating or one or more layers of sintered polyethylene coating. These coatings are specifically designed to provide excellent corrosion protection for steel pipe and fittings, making them ideal for a variety of applications such as oil and gas, water transportation and infrastructure projects. The three-layer system typically consists of an epoxy primer, a middle layer of adhesive, and an outer layer of polyethylene, which together form a strong barrier against environmental elements.

Key features of FBE coated pipes include excellent adhesion, resistance to cathodic disbondment, and superior mechanical strength. These properties not only extend the life of the pipe but also reduce maintenance costs, making it an affordable choice for businesses.

Product Advantage

One of the main benefits of FBE coated pipe is its excellent corrosion resistance. The polyethylene coating creates a strong barrier that protects the steel from moisture and other corrosive elements, extending the life of the pipe. Additionally, the factory-applied nature of these coatings ensures a uniform application, reducing the risk of defects that can occur with field-applied coatings. This consistency improves reliability and performance in a variety of applications, from oil and gas to water supply.

Additionally, FBE coatings are known for their excellent adhesion, which increases the overall durability of the pipe. They can also withstand high temperatures, making them suitable for a wide range of industrial applications.

Product Shortcoming

One notable issue is that they are easily damaged during installation. If the coating is scratched or damaged, it can cause corrosion in exposed areas. Additionally, while FBE coatings are effective against many corrosive substances, they may not be suitable for all chemical environments, so specific applications need to be carefully considered.

FAQS

Q1. What are the main advantages of FBE coating?

FBE coatings offer excellent adhesion, chemical resistance and mechanical protection. They are particularly effective in harsh environments and are ideal for underground and underwater applications.

Q2. How is FBE coating applied?

The application process involves heating the epoxy powder and applying it to the preheated surface of the steel pipe, ensuring a strong bond, thereby enhancing the durability of the pipe.

Q3. Where are FBE coated pipes produced?

Our FBE coated pipes are manufactured in our state-of-the-art factory located in Cangzhou City, Hebei Province. Established in 1993, our factory covers an area of 350,000 square meters and employs 680 skilled workers to ensure high quality production standards.

Q4. What industries can benefit from FBE coated pipe?

Industries such as oil and gas, water treatment and construction benefit significantly from the corrosion resistance and long life of FBE coated pipes.