PriceList For Stainless Steel Gas Pipe - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral

PriceList For Stainless Steel Gas Pipe - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral Detail:

Physical properties of epoxy powder materials

Specific gravity at 23℃: minimum 1.2 and maximum 1.8

Sieve analysis: maximum 2.0

Gel time at 200 ℃: less than 120s

Abrasive blast cleaning

Bare steel surfaces shall be abrasive blast-cleaned in accordance with SSPC-SP10/NACE No. 2 unless otherwise specified by the purchaser. The blast anchor pattern or profile depth shall be 1.5 mil to 4.0 mil(38 µm to 102 µm) measured in accordance with ASTM D4417.

Preheating

Pipe that has been cleaned shall be preheated at temperature less than 260℃, the heat source shall not contaminate the pipe surface.

Thickness

The coating powder shall be applied to the preheated pipe at a uniform cure-film thickness of not less than 12 mils(305μm) on the exterior or interior. The maximum thickness shall not exceed a nominal 16 mils(406μm) unless recommended by the manufacturer or specified by the pruchaser.

Optional epoxy performance testing

The purchaser may specify additional testing to establish epoxy performance. The following test procedures, all of which shall be performed on production pipe test rings, may be specified:

1. Cross-section porosity.

2. Interface porosity.

3. Thermal analysis (DSC).

4. Permanent strain (bendability).

5. Water soak.

6. Impact.

7. Cathodic disbondment test.

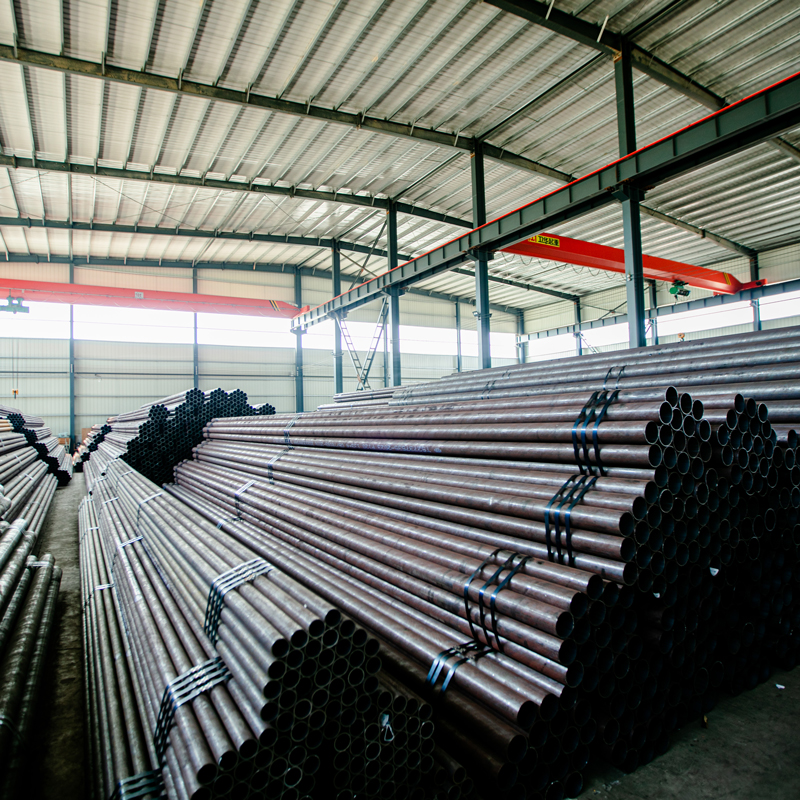

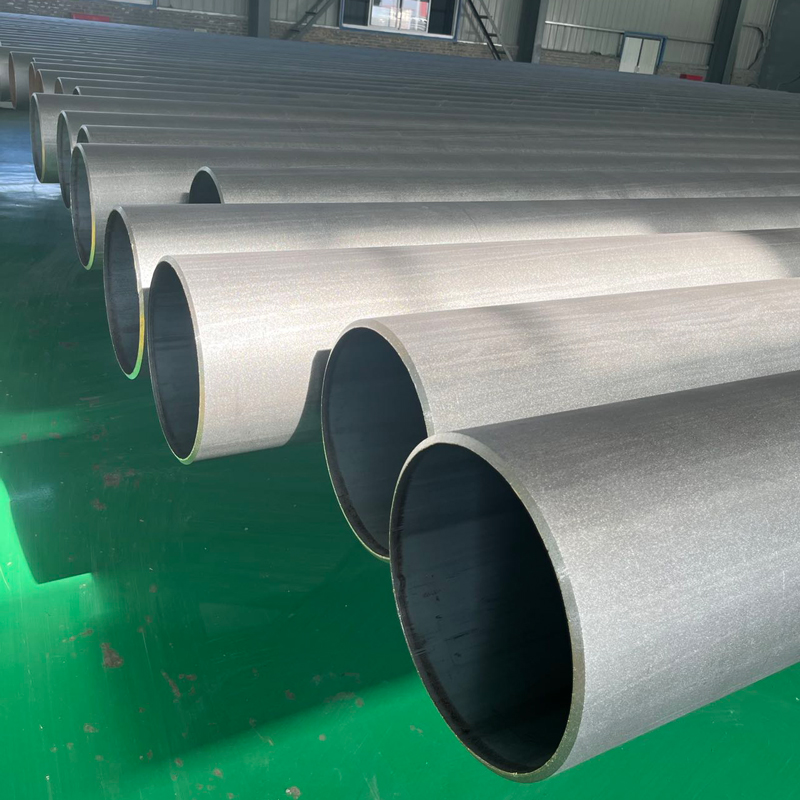

Product detail pictures:

Related Product Guide:

We not only will try our best to offer excellent services to every customer, but also are ready to receive any suggestion offered by our customers for PriceList For Stainless Steel Gas Pipe - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral , The product will supply to all over the world, such as: Luxemburg, Slovak Republic, Poland, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.