One Of Hottest For Gas Pipe Line - Cold Formed Pipes, EN10219 S235JRH, S235J0H, S355JRH, S355J0H – Spiral

One Of Hottest For Gas Pipe Line - Cold Formed Pipes, EN10219 S235JRH, S235J0H, S355JRH, S355J0H – Spiral Detail:

Mechanical Property

|

steel grade |

minimum yield strength |

Tensile strength |

Minimum elongation |

Minimum impact energy |

||||

|

Specified thickness |

Specified thickness |

Specified thickness |

at test temperature of |

|||||

|

<16 |

>16≤40 |

<3 |

≥3≤40 |

≤40 |

-20℃ |

0℃ |

20℃ |

|

| S235JRH |

235 |

225 |

360-510 |

360-510 |

24 |

- |

- |

27 |

| S275J0H |

275 |

265 |

430-580 |

410-560 |

20 |

- |

27 |

- |

| S275J2H |

27 |

- |

- |

|||||

| S355J0H |

365 |

345 |

510-680 |

470-630 |

20 |

- |

27 |

- |

| S355J2H |

27 |

- |

- |

|||||

| S355K2H |

40 |

- |

- |

|||||

Chemical Composition

|

Steel grade |

Type of de-oxidation a |

% by mass, maximum |

||||||

|

Steel name |

Steel number |

C |

C |

Si |

Mn |

P |

S |

Nb |

|

S235JRH |

1.0039 |

FF |

0,17 |

— |

1,40 |

0,040 |

0,040 |

0.009 |

|

S275J0H |

1.0149 |

FF |

0,20 |

— |

1,50 |

0,035 |

0,035 |

0,009 |

|

S275J2H |

1.0138 |

FF |

0,20 |

— |

1,50 |

0,030 |

0,030 |

— |

|

S355J0H |

1.0547 |

FF |

0,22 |

0,55 |

1,60 |

0,035 |

0,035 |

0,009 |

|

S355J2H |

1.0576 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

S355K2H |

1.0512 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

a. The deoxidation method is designated as follows: FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al). b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. |

||||||||

Hydrostatic Test

Each length of pipe shall be tested by the manufacturer to a hydrostatic pressure that will produce in the pipe wall a stress of not less than 60% of the specified minimum yield strength at room temperature. The pressure shall be determined by the following equation:

P=2St/D

Permissible Variations In Weights and Dimensions

Each length of pipe shall be weighed separately and its weight shall not vary more than 10% over or 5.5% under its theoretical weight, calculated using its length and its weight per unit length

The outside diameter shall not vary more than ±1% from the specified nominal outside diameter

Wall thickness at any point shall not more than 12.5% under the specified wall thickness

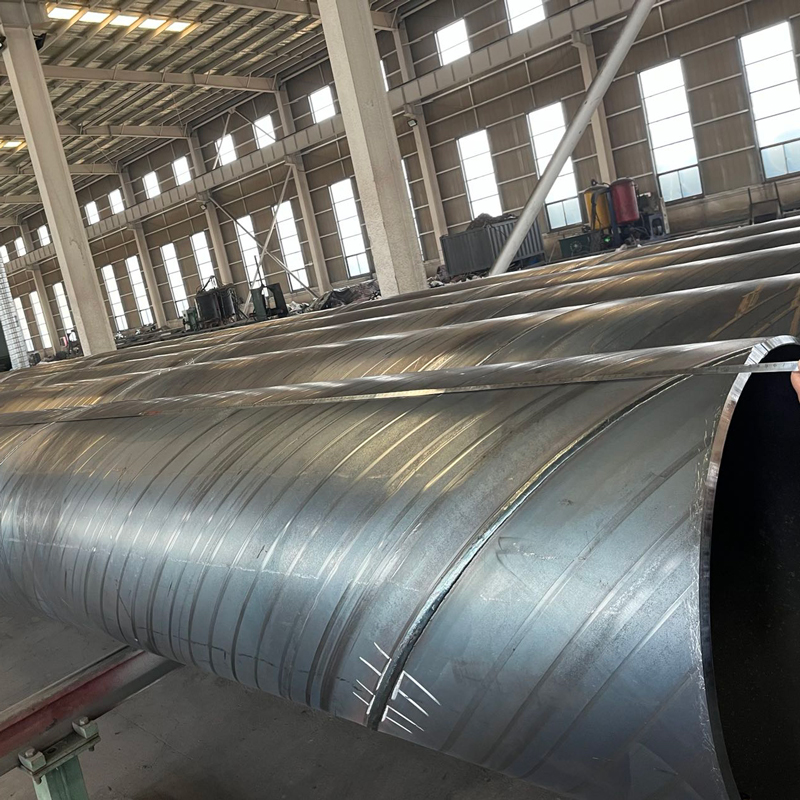

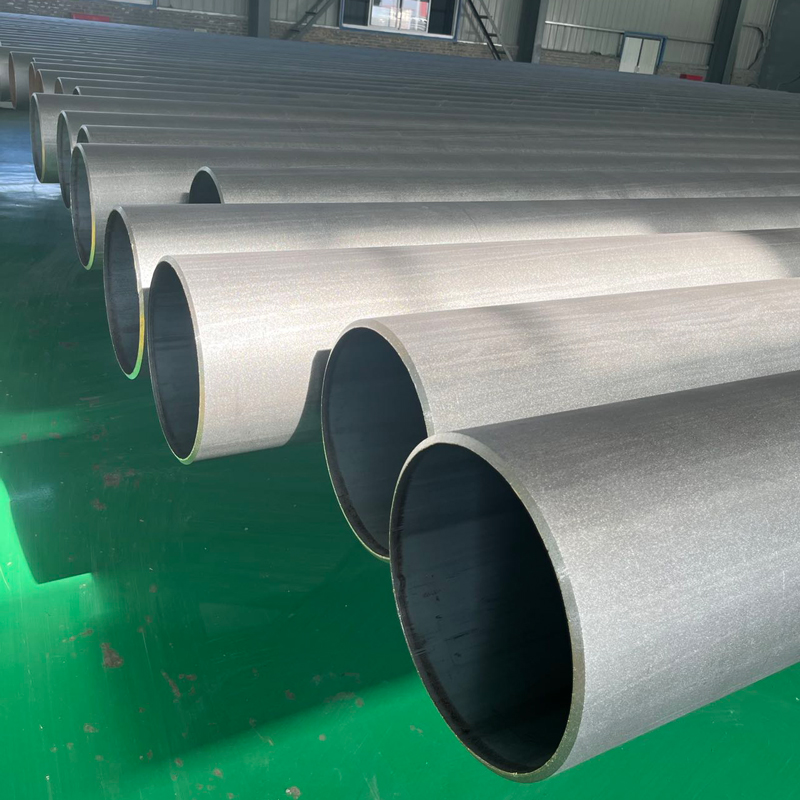

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for One Of Hottest For Gas Pipe Line - Cold Formed Pipes, EN10219 S235JRH, S235J0H, S355JRH, S355J0H – Spiral , The product will supply to all over the world, such as: Cancun, Austria, Eindhoven, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!