OEM/ODM Manufacturer Potable Water Line - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral

OEM/ODM Manufacturer Potable Water Line - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral Detail:

Physical properties of epoxy powder materials

Specific gravity at 23℃: minimum 1.2 and maximum 1.8

Sieve analysis: maximum 2.0

Gel time at 200 ℃: less than 120s

Abrasive blast cleaning

Bare steel surfaces shall be abrasive blast-cleaned in accordance with SSPC-SP10/NACE No. 2 unless otherwise specified by the purchaser. The blast anchor pattern or profile depth shall be 1.5 mil to 4.0 mil(38 µm to 102 µm) measured in accordance with ASTM D4417.

Preheating

Pipe that has been cleaned shall be preheated at temperature less than 260℃, the heat source shall not contaminate the pipe surface.

Thickness

The coating powder shall be applied to the preheated pipe at a uniform cure-film thickness of not less than 12 mils(305μm) on the exterior or interior. The maximum thickness shall not exceed a nominal 16 mils(406μm) unless recommended by the manufacturer or specified by the pruchaser.

Optional epoxy performance testing

The purchaser may specify additional testing to establish epoxy performance. The following test procedures, all of which shall be performed on production pipe test rings, may be specified:

1. Cross-section porosity.

2. Interface porosity.

3. Thermal analysis (DSC).

4. Permanent strain (bendability).

5. Water soak.

6. Impact.

7. Cathodic disbondment test.

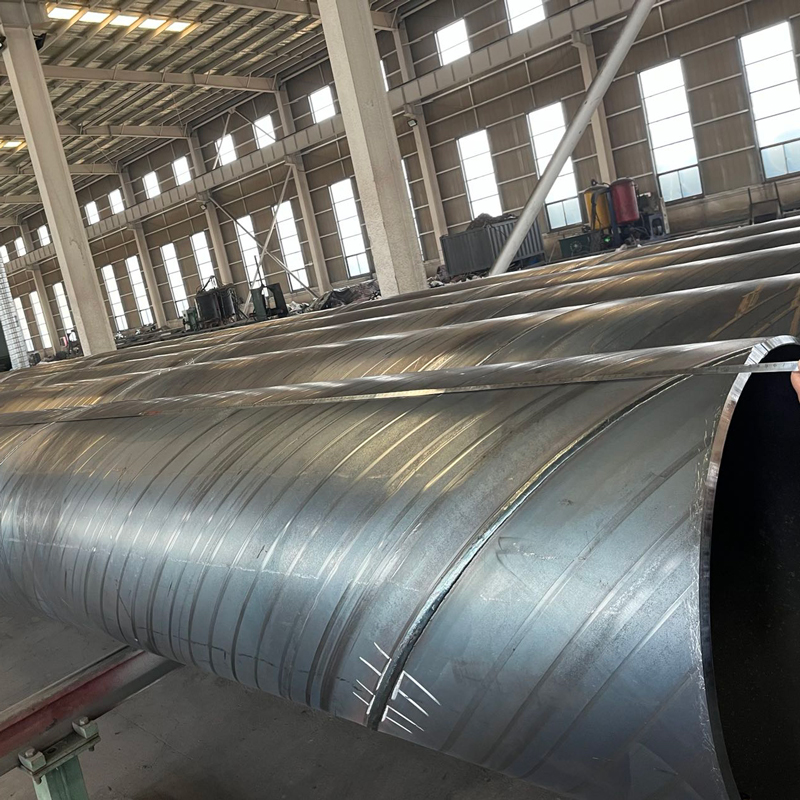

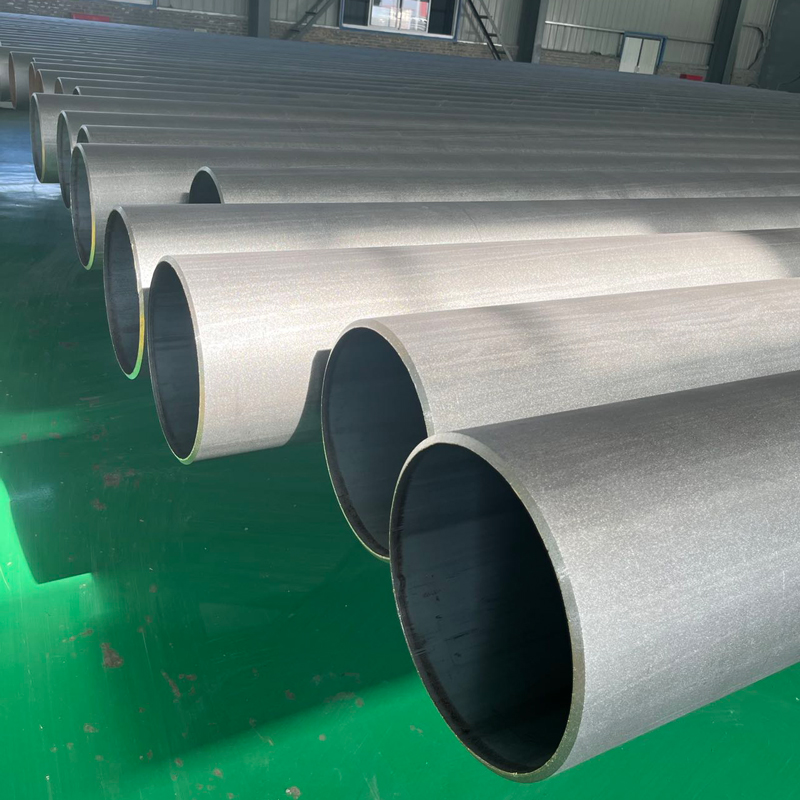

Product detail pictures:

Related Product Guide:

Our firm sticks on the theory of Quality will be the life in the enterprise, and status could be the soul of it for OEM/ODM Manufacturer Potable Water Line - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral , The product will supply to all over the world, such as: Dominica, Georgia, Belize, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.