OEM Factory For Water Line Tubing - Outside 3LPE coating DIN 30670 inside FBE coating – Spiral

OEM Factory For Water Line Tubing - Outside 3LPE coating DIN 30670 inside FBE coating – Spiral Detail:

Product Description

Cangzhou Spiral Steel Pipes Group Co., Ltd have 4 production lines of anticorrosion & thermal insulation to perform the 3LPE coating and FBE coating. The maximum outside diameter can be 2600mm.

The coatings are suitable for the protection of buried or submerged steel pipes at design temperatures of -40℃ to +80℃.

The present standard specifies requirements for coatings that are applied to spirally welded steel pipes and fittings used for the construction of pipelines for conveying liquids or gases.

Applying this standard ensures that the PE coating provides sufficient protection against the mechanical thermal and chemical loads occurring during operation, transport, storage and installation.

Extruded coatings comprise three layers: an epoxy resin primer, a PE adhesive and an extruded polyethylene outer layer. The epoxy resin primer is applied as a powder. The adhesive can be applied either as a powder or by extrusion. For extruded coatings a differentiation is made between sleeve extrusion and sheet extrusion. Sintered polyethylene coatings are single or multi-layer systems. The polyethylene powder is fused onto the pre-heated component until the desired coating thickness is reached.

Epoxy resin primer

The epoxy resin primer is to be applied in powder form. The minimum layer thickness is 60μm.

PE adhesive

The PE adhesive can be applied in powder form or extruded. The minimum layer thickness is 140μm. the peel strength requirements vary depending on whether the adhesive was applied as a powder or was extruded.

Polyethylene coating

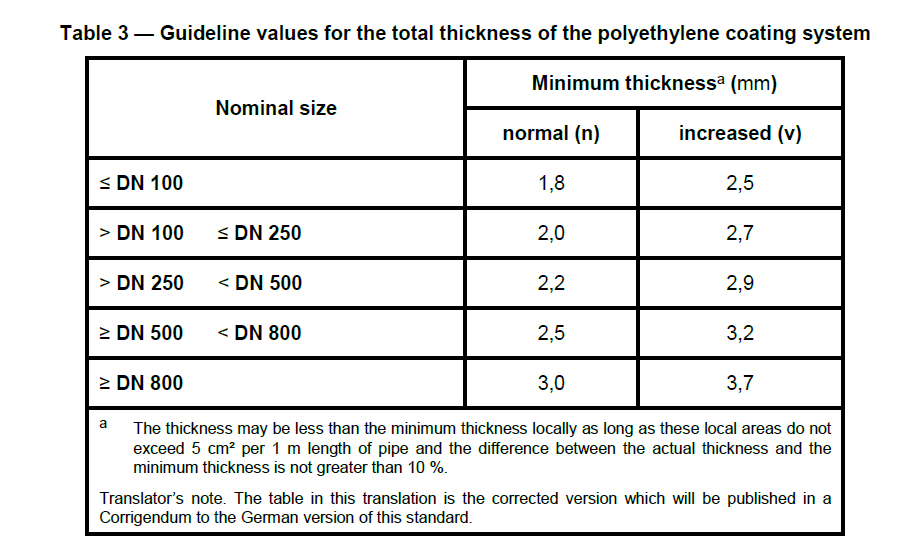

The polyethylene coating is applied either by sintering or by sleeve or sheet extrusion. The coating is to be cooled after application to avoid unwanted deformation during transport. Depending on the nominal size, there are different minimum values for the normal total coating thickness. In the case of increased mechanical loads the minimu layer thickess shall be increased by 0.7mm. minimum layer thickness are given in table 3 below.

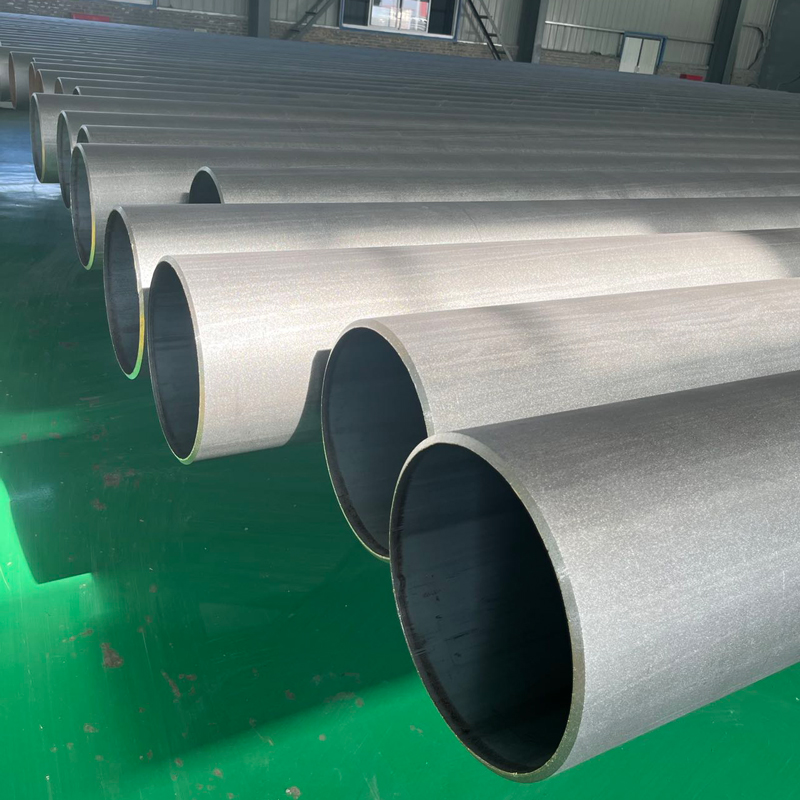

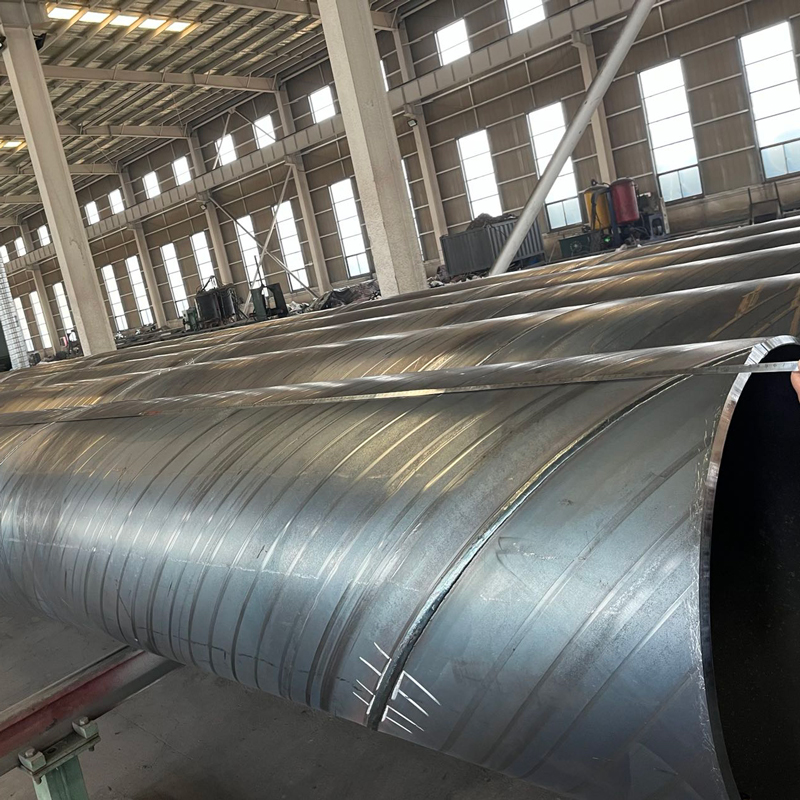

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for OEM Factory For Water Line Tubing - Outside 3LPE coating DIN 30670 inside FBE coating – Spiral , The product will supply to all over the world, such as: Kuwait, Berlin, Qatar, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!