OEM Factory For Gas Line For Stove - Cold Formed Pipes, EN10219 S235JRH, S235J0H, S355JRH, S355J0H – Spiral

OEM Factory For Gas Line For Stove - Cold Formed Pipes, EN10219 S235JRH, S235J0H, S355JRH, S355J0H – Spiral Detail:

Mechanical Property

|

steel grade |

minimum yield strength |

Tensile strength |

Minimum elongation |

Minimum impact energy |

||||

|

Specified thickness |

Specified thickness |

Specified thickness |

at test temperature of |

|||||

|

<16 |

>16≤40 |

<3 |

≥3≤40 |

≤40 |

-20℃ |

0℃ |

20℃ |

|

| S235JRH |

235 |

225 |

360-510 |

360-510 |

24 |

- |

- |

27 |

| S275J0H |

275 |

265 |

430-580 |

410-560 |

20 |

- |

27 |

- |

| S275J2H |

27 |

- |

- |

|||||

| S355J0H |

365 |

345 |

510-680 |

470-630 |

20 |

- |

27 |

- |

| S355J2H |

27 |

- |

- |

|||||

| S355K2H |

40 |

- |

- |

|||||

Chemical Composition

|

Steel grade |

Type of de-oxidation a |

% by mass, maximum |

||||||

|

Steel name |

Steel number |

C |

C |

Si |

Mn |

P |

S |

Nb |

|

S235JRH |

1.0039 |

FF |

0,17 |

— |

1,40 |

0,040 |

0,040 |

0.009 |

|

S275J0H |

1.0149 |

FF |

0,20 |

— |

1,50 |

0,035 |

0,035 |

0,009 |

|

S275J2H |

1.0138 |

FF |

0,20 |

— |

1,50 |

0,030 |

0,030 |

— |

|

S355J0H |

1.0547 |

FF |

0,22 |

0,55 |

1,60 |

0,035 |

0,035 |

0,009 |

|

S355J2H |

1.0576 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

S355K2H |

1.0512 |

FF |

0,22 |

0,55 |

1,60 |

0,030 |

0,030 |

— |

|

a. The deoxidation method is designated as follows: FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al). b. The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. |

||||||||

Hydrostatic Test

Each length of pipe shall be tested by the manufacturer to a hydrostatic pressure that will produce in the pipe wall a stress of not less than 60% of the specified minimum yield strength at room temperature. The pressure shall be determined by the following equation:

P=2St/D

Permissible Variations In Weights and Dimensions

Each length of pipe shall be weighed separately and its weight shall not vary more than 10% over or 5.5% under its theoretical weight, calculated using its length and its weight per unit length

The outside diameter shall not vary more than ±1% from the specified nominal outside diameter

Wall thickness at any point shall not more than 12.5% under the specified wall thickness

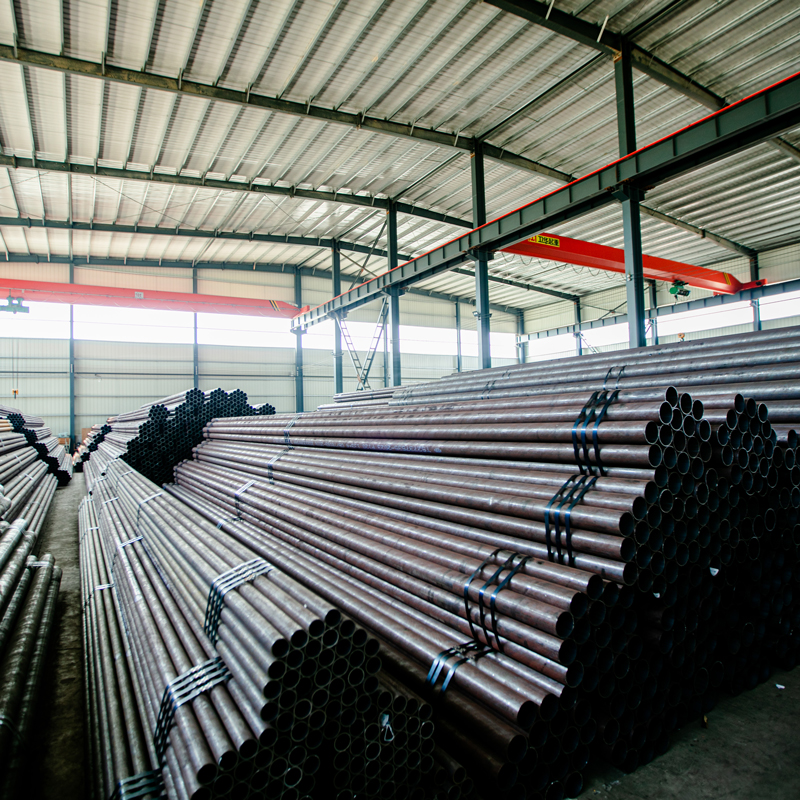

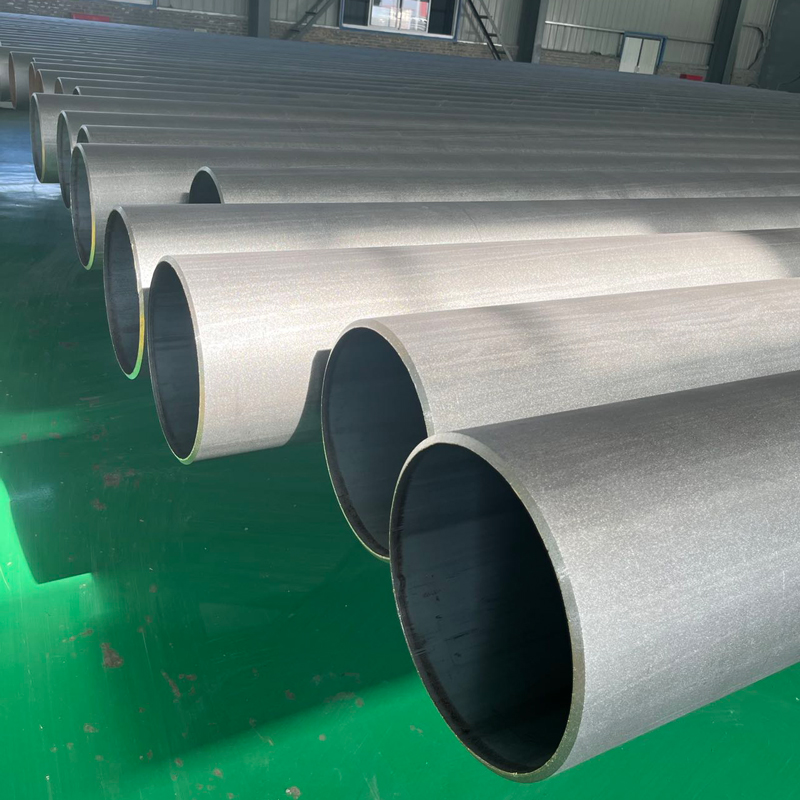

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science as well as the theory of quality the basic, have confidence in the very first and management the advanced for OEM Factory For Gas Line For Stove - Cold Formed Pipes, EN10219 S235JRH, S235J0H, S355JRH, S355J0H – Spiral , The product will supply to all over the world, such as: Danish, Hongkong, Ukraine, Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.