In industrial applications, especially in the oil and gas sector, the integrity of steel pipe is critical. One of the most effective ways to ensure the longevity and durability of these pipes is with the use of fusion bonded epoxy (FBE) coatings. Understanding FBE coating standards is critical for anyone involved in the purchase, installation or maintenance of steel water pipe and fittings.

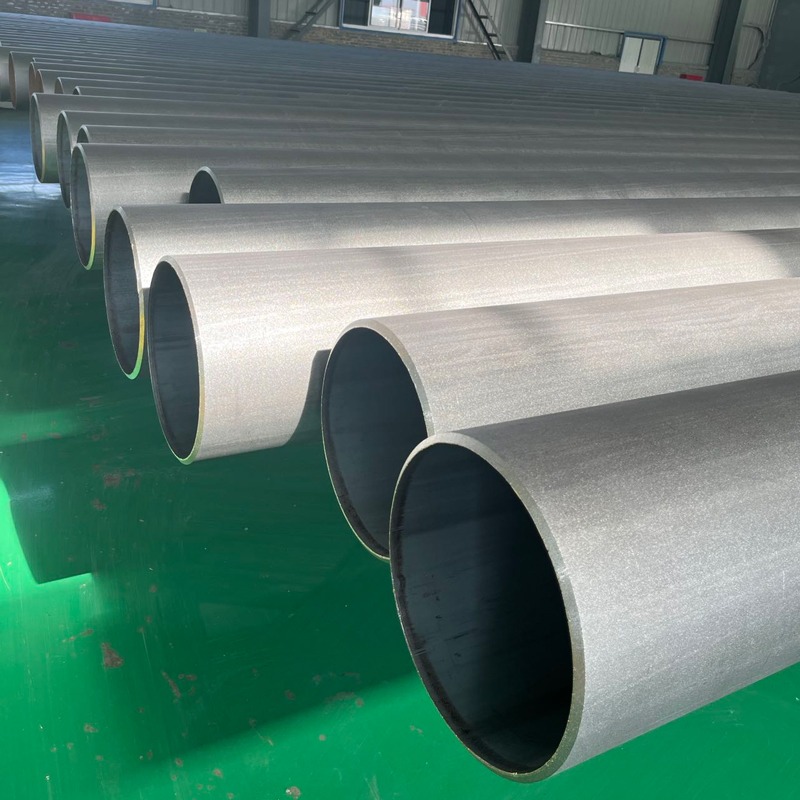

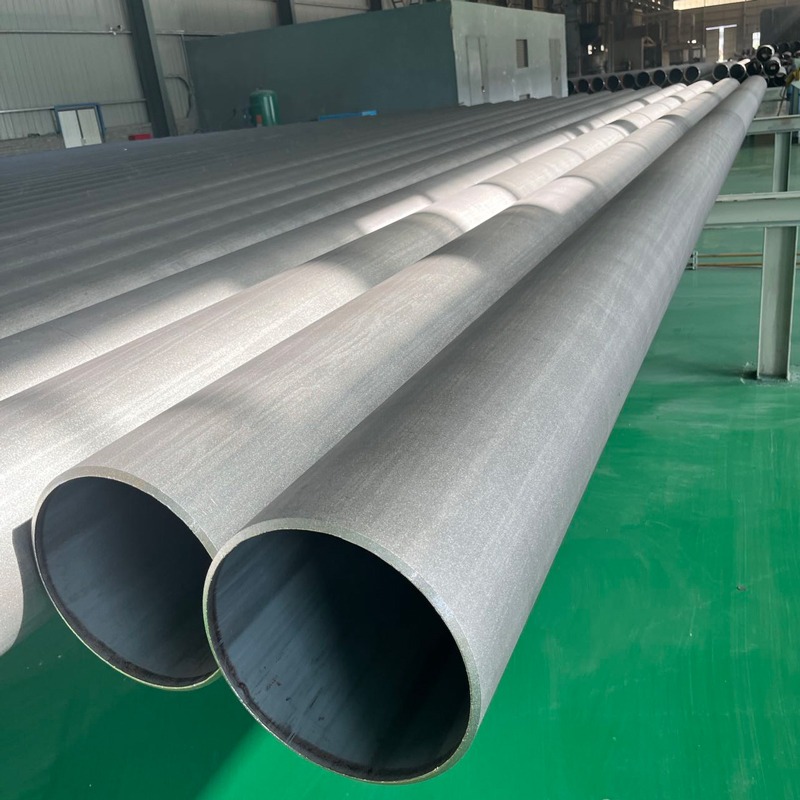

FBE coatings are mainly used on various types of steel pipes, including SSAW (Spiral Submerged Arc Welded) pipes, ERW (Electric Resistance Welded) pipes, LSAW (Longitudinal Submerged Arc Welded) pipes, seamless pipes, and various fittings such as elbows, tees, and reducers. The main purpose of these coatings is to provide corrosion protection, which is essential to maintain the structural integrity of the pipeline in the long term.

What is FBE coating?

FBE coating is a thermosetting epoxy powder applied to the surface of steel pipe. The application process involves heating the pipe to a specific temperature and then applying the epoxy powder, which melts and forms a strong bond with the steel pipe surface. This process creates a smooth, durable and chemically resistant coating that can withstand harsh environmental conditions.

Importance of FBE coating standards

Compliance with FBE coating standards is critical for the following reasons:

1. Corrosion resistance: The main function of FBE coating is to protect steel from corrosion. Relevant standards ensure that the coating is applied correctly and meets the necessary thickness and adhesion requirements to provide optimal protection.

2. Quality Assurance: By following established standards, manufacturers can guarantee the quality of their products. This is especially important for companies that produce large quantities of steel pipes, for example, a company with total assets of 680 million yuan, an annual output of 400,000 tons of spiral steel pipes, and an output value of 1.8 billion yuan.

3. Compliance: Many industries are subject to strict regulation of the materials and processes in which they operate. Complying with FBE coating standards helps companies avoid legal issues and maintain their market reputation.

4. Long-lasting and reliable: Proper application of FBE coating can significantly extend the service life of steel pipes. This reliability is critical for industries that rely on these pipes to transport water, oil and gas.

When considering FBE coatings, it is important to understand the key criteria for their application:

- ASTM D638: This standard outlines the tensile properties of plastics (including FBE coatings) to ensure they can withstand the stresses encountered in use.

- ASTM D3359: This standard tests the adhesion of the coating to the substrate, which is critical to ensuring that the FBE coating remains intact over time.

- AWWA C213: This standard specifically addresses the requirements for fusion-bonded epoxy coatings for steel water pipe, providing guidance for application, inspection, and testing.

in conclusion

In summary, understanding FBE coating standards is critical for anyone involved in the steel pipe industry. Focusing on corrosion protection, quality assurance, and regulatory compliance, these standards play a vital role in ensuring the service life and reliability of steel pipes and fittings. Companies that place a premium on adhering to these standards, such as those with strong production capabilities and assets, can not only improve product quality but also strengthen their position in a competitive market. As the demand for durable and reliable steel pipe continues to grow, the importance of FBE coatings and the standards for their application will continue to grow.

Post time: Jun-11-2025