Manufacturer For Sewer Line Pipe - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral

Manufacturer For Sewer Line Pipe - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral Detail:

Physical properties of epoxy powder materials

Specific gravity at 23℃: minimum 1.2 and maximum 1.8

Sieve analysis: maximum 2.0

Gel time at 200 ℃: less than 120s

Abrasive blast cleaning

Bare steel surfaces shall be abrasive blast-cleaned in accordance with SSPC-SP10/NACE No. 2 unless otherwise specified by the purchaser. The blast anchor pattern or profile depth shall be 1.5 mil to 4.0 mil(38 µm to 102 µm) measured in accordance with ASTM D4417.

Preheating

Pipe that has been cleaned shall be preheated at temperature less than 260℃, the heat source shall not contaminate the pipe surface.

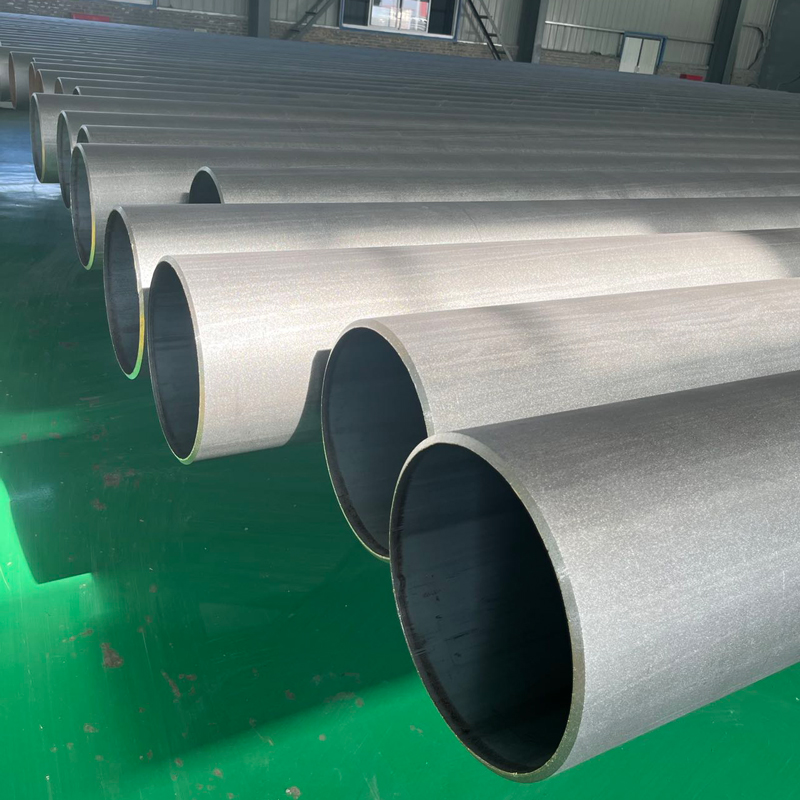

Thickness

The coating powder shall be applied to the preheated pipe at a uniform cure-film thickness of not less than 12 mils(305μm) on the exterior or interior. The maximum thickness shall not exceed a nominal 16 mils(406μm) unless recommended by the manufacturer or specified by the pruchaser.

Optional epoxy performance testing

The purchaser may specify additional testing to establish epoxy performance. The following test procedures, all of which shall be performed on production pipe test rings, may be specified:

1. Cross-section porosity.

2. Interface porosity.

3. Thermal analysis (DSC).

4. Permanent strain (bendability).

5. Water soak.

6. Impact.

7. Cathodic disbondment test.

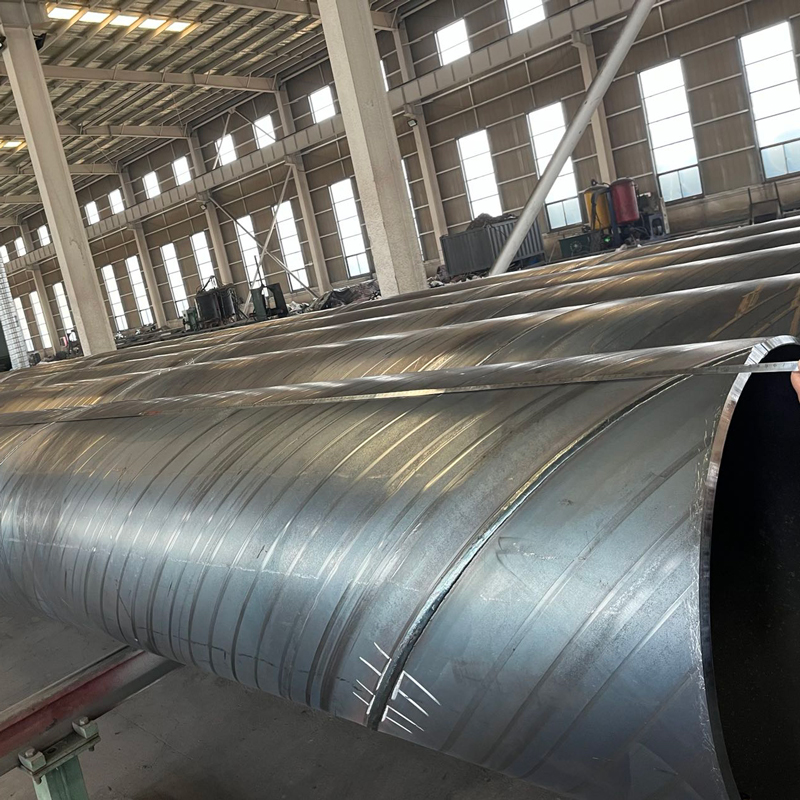

Product detail pictures:

Related Product Guide:

Sticking towards the principle of Super High-quality, Satisfactory service ,We've been striving to become a superb business partner of you for Manufacturer For Sewer Line Pipe - Fusion-Bonded Epoxy Coatings Awwa C213 Standard – Spiral , The product will supply to all over the world, such as: Portland, Puerto Rico, Gambia, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.