Hot-Selling Helical Submerged Arc Welding - ASTM A234 WPB & WPC pipe fittings including elbows, tee, reducers – Spiral

Hot-Selling Helical Submerged Arc Welding - ASTM A234 WPB & WPC pipe fittings including elbows, tee, reducers – Spiral Detail:

Chemical Composition of ASTM A234 WPB & WPC

|

Element |

Content, % |

|

|

ASTM A234 WPB |

ASTM A234 WPC |

|

|

Carbon [C] |

≤0.30 |

≤0.35 |

|

Manganese [Mn] |

0.29-1.06 |

0.29-1.06 |

|

Phosphorus [P] |

≤0.050 |

≤0.050 |

|

Sulfur [S] |

≤0.058 |

≤0.058 |

|

Silicon [Si] |

≥0.10 |

≥0.10 |

|

Chromium [Cr] |

≤0.40 |

≤0.40 |

|

Molybdenum [Mo] |

≤0.15 |

≤0.15 |

|

Nickel [Ni] |

≤0.40 |

≤0.40 |

|

Copper [Cu] |

≤0.40 |

≤0.40 |

|

Vanadium [V] |

≤0.08 |

≤0.08 |

*The Carbon Equivalent [C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15] shall be no greater than 0.50 and shall be reported on MTC.

Mechanical Properties of ASTM A234 WPB & WPC

|

ASTM A234 Grades |

Tensile Strength, min. |

Yield Strength, min. |

Elongation %, min |

|||

|

ksi |

MPa |

ksi |

MPa |

Longitudinal |

Transverse |

|

|

WPB |

60 |

415 |

35 |

240 |

22 |

14 |

|

WPC |

70 |

485 |

40 |

275 |

22 |

14 |

*1. WPB and WPC pipe fittings manufactured from plates shall have a minimum elongation of 17%.

*2. Unless required, hardness value doesn’t need to be reported.

Manufacture

The ASTM A234 carbon steel pipe fittings may be made from seamless pipes, welded pipes or plates by shaping operations of pressing, piercing, extruding, bending, fusion welding, machining, or by a combination of two or more these operations. All welds including welds in tubular products from which fittings are made shall be made in accordance with ASME Section IX. Post-weld heat treatment at 1100 to 1250°F[595 to 675°C] and radiographic examination shall be performed after the welding process.

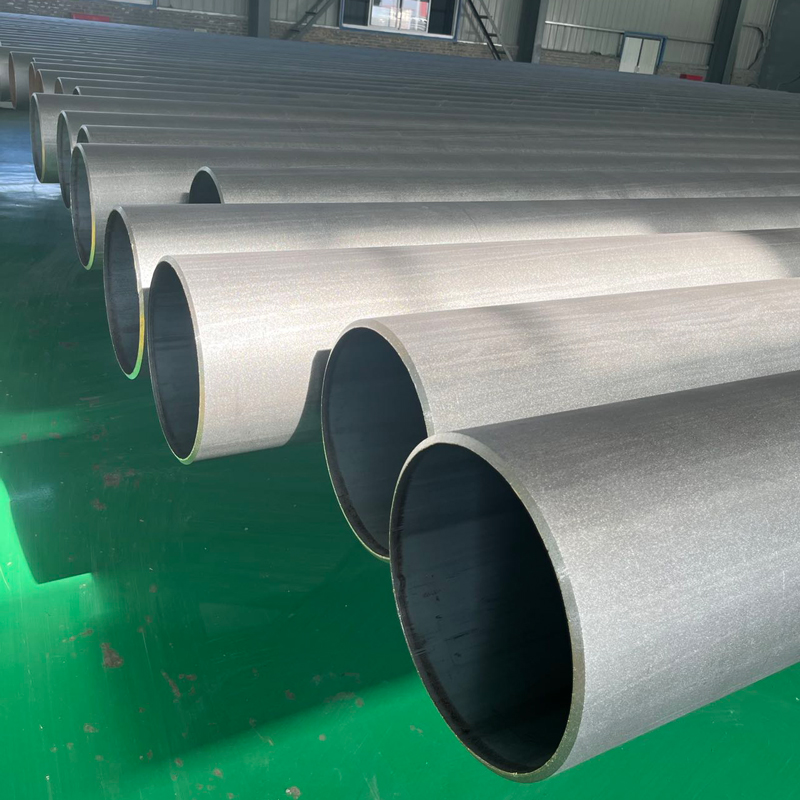

Product detail pictures:

Related Product Guide:

Our business sticks for the basic principle of Quality could be the life with the firm, and track record will be the soul of it for Hot-Selling Helical Submerged Arc Welding - ASTM A234 WPB & WPC pipe fittings including elbows, tee, reducers – Spiral , The product will supply to all over the world, such as: Cape Town, Slovakia, New Zealand, Our company regards reasonable prices, efficient production time and good after-sales service as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.