Best Quality Spiral Submerged Arc Pipe - Api 5l Line Pipes Grade B To X70 Od From 219mm To 3500mm – Spiral

Best Quality Spiral Submerged Arc Pipe - Api 5l Line Pipes Grade B To X70 Od From 219mm To 3500mm – Spiral Detail:

The Mechanical Properties of the SSAW pipe

|

steel grade |

minimum yield strength |

minimum Tensile strength |

Minimum Elongation |

|

B |

245 |

415 |

23 |

|

X42 |

290 |

415 |

23 |

|

X46 |

320 |

435 |

22 |

|

X52 |

360 |

460 |

21 |

|

X56 |

390 |

490 |

19 |

|

X60 |

415 |

520 |

18 |

|

X65 |

450 |

535 |

18 |

|

X70 |

485 |

570 |

17 |

The Chemical composition of the SSAW pipes

|

steel grade |

C |

Mn |

P |

S |

V+Nb+Ti |

|

Max % |

Max % |

Max % |

Max % |

Max % |

|

|

B |

0.26 |

1.2 |

0.03 |

0.03 |

0.15 |

|

X42 |

0.26 |

1.3 |

0.03 |

0.03 |

0.15 |

|

X46 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X52 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X56 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X60 |

0.26 |

1.4 |

0.03 |

0.03 |

0.15 |

|

X65 |

0.26 |

1.45 |

0.03 |

0.03 |

0.15 |

|

X70 |

0.26 |

1.65 |

0.03 |

0.03 |

0.15 |

The Geometric tolerance of the SSAW pipes

|

Geometric tolerances |

||||||||||

|

outside diameter |

Wall thickness |

straightness |

out-of-roundness |

mass |

Maximum weld bead height |

|||||

|

D |

T |

|||||||||

|

≤1422mm |

>1422mm |

<15mm |

≥15mm |

pipe end 1.5m |

full length |

pipe body |

pipe end |

T≤13mm |

T>13mm |

|

|

±0.5% |

as agreed |

±10% |

±1.5mm |

3.2mm |

0.2% L |

0.020D |

0.015D |

‘+10% |

3.5mm |

4.8mm |

Hydrostatic Test

The pipe shall withstand the hydrostatic test without leakage through the weld seam or the pipe body

Jointers need not be hydrostatically tested, providedthat the portions of pipe used in marking the jointers were successfully hydrostatically tested prior to the joining operation.

Traceablity:

For PSL 1 pipe, the manufacturer shall establish and follow documented procedures for maintaining:

The heat identity until each related chmical tests is performed and conformance with the specified requirements is shown

The test-unit identity until each related mechanical tests is performed and conformance with the specified requirements is shown

For PSL 2 pipe, the manufacturer shall establish and follow documented procedures for maintaining the heat identity and the test-unit identity for such pipe. Such procedures shall provide means for tracing any length of pipe to the proper test unit and the related chemical test results.

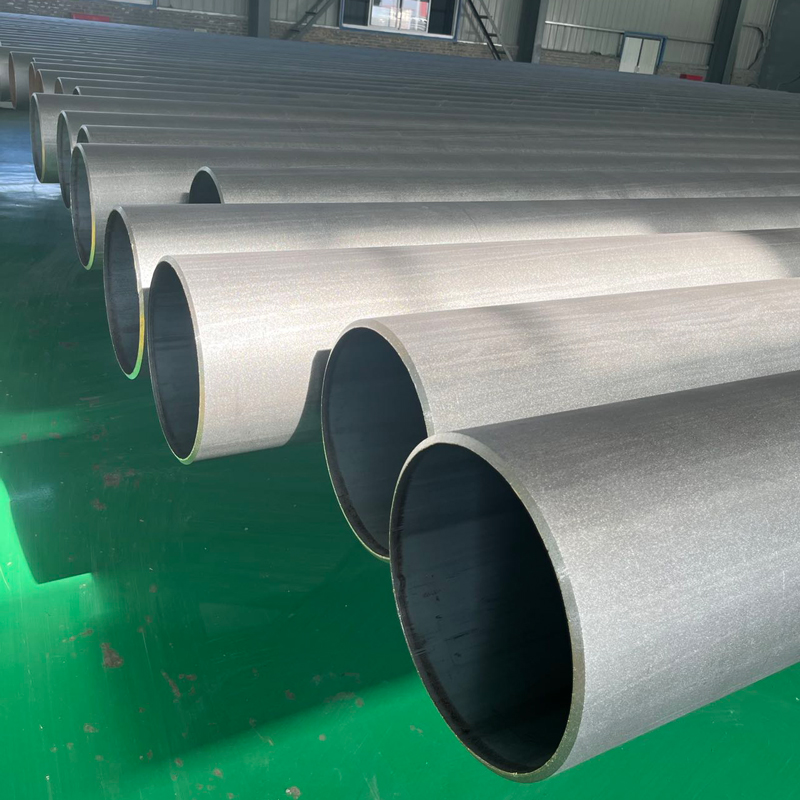

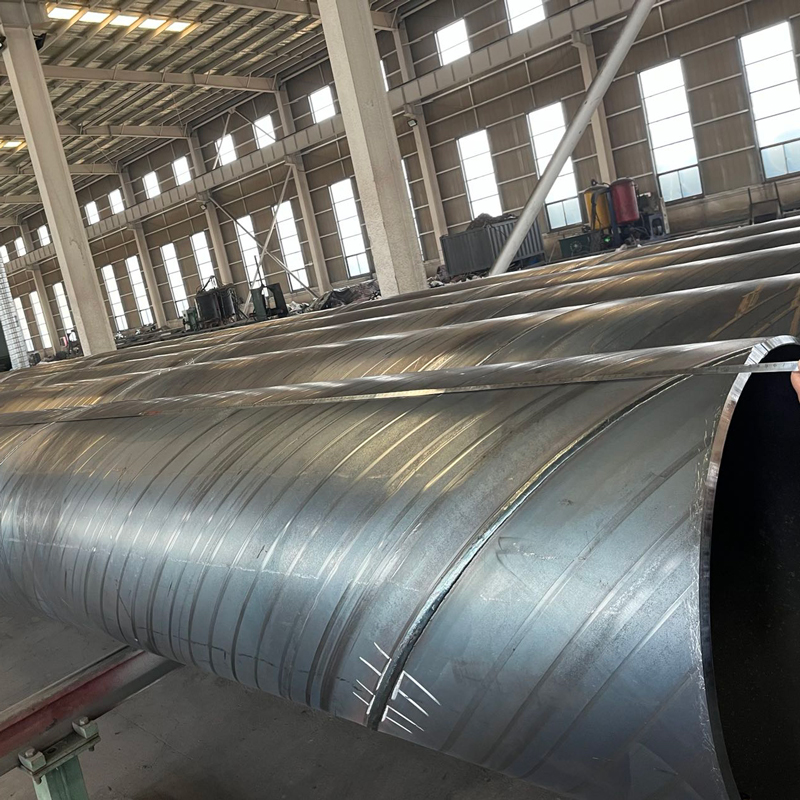

Product detail pictures:

Related Product Guide:

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for Best Quality Spiral Submerged Arc Pipe - Api 5l Line Pipes Grade B To X70 Od From 219mm To 3500mm – Spiral , The product will supply to all over the world, such as: Gabon, Johor, Oman, Our company is working by the operation principle of integrity-based, cooperation created, people oriented, win-win cooperation. We hope we can have a friendly relationship with businessman from all over the world.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!