Advanced Oil Pipe Line System

The Mechanical Properties Of The SSAW Pipe

| steel grade | minimum yield strength Mpa |

minimum Tensile strength Mpa |

Minimum Elongation % |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| X56 | 390 | 490 | 19 |

| X60 | 415 | 520 | 18 |

| X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

The Chemical Composition Of The SSAW Pipes

| steel grade | C | Mn | P | S | V+Nb+Ti |

| Max % | Max % | Max % | Max % | Max % | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

The Geometric Tolerance Of The SSAW Pipes

| Geometric tolerances | ||||||||||

| outside diameter | Wall thickness | straightness | out-of-roundness | mass | Maximum weld bead height | |||||

| D | T | |||||||||

| ≤1422mm | >1422mm | <15mm | ≥15mm | pipe end 1.5m | full length | pipe body | pipe end | T≤13mm | T>13mm | |

| ±0.5% ≤4mm |

as agreed | ±10% | ±1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | ‘+10% -3.5% |

3.5mm | 4.8mm |

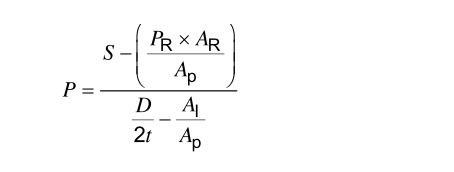

Hydrostatic Test

Product Introduction

Introducing Advanced Petroleum Pipe Systems: The future of efficient and reliable energy transportation. As the demand for oil and gas continues to grow, the need for strong and reliable pipes has never been greater. Our X60 SSAW pipes are at the forefront of this development, designed specifically for petroleum pipeline construction and manufactured to the highest industry standards.

X60 SSAW line pipe is a spiral steel pipe that offers a variety of benefits, including enhanced strength, flexibility and corrosion resistance. These features make it ideal for transporting oil and gas over long distances, ensuring that energy reaches its destination safely and efficiently. Our advanced oil pipe line systems are designed to withstand the rigors of harsh environments, providing peace of mind for operators and stakeholders.

Product Advantage

One of the main advantages of X60 SSAW line pipe is its rugged construction. Made from high-quality steel, this spiral pipe can withstand high pressures and harsh environmental conditions, making it ideal for transporting oil and gas over long distances. In addition, the spiral welding process allows for continuous pipe lengths, reducing the number of joints and potential leak points, thereby improving the overall reliability of the pipeline system.

Additionally, X60 SSAW line pipe is known for its cost-effectiveness. The manufacturing process is efficient, allowing for competitive pricing without compromising quality. This is particularly beneficial for companies looking to optimize operating costs while ensuring the safety and integrity of their pipeline systems.

Product Shortcoming

X60 SSAW linepipe may not be suitable for all types of terrain or environmental conditions. In areas with extreme temperatures or high levels of seismic activity, additional engineering solutions may be required to ensure the integrity of the pipe. Additionally, while spiral welding technology offers many advantages, it can also lead to inspection and maintenance challenges, as the weld seam may be more difficult to access than straight seam pipe.

Application

As the global demand for oil and gas continues to surge, the need for efficient and reliable transportation systems has never been more urgent. One of the most effective solutions to this challenge is advanced oil pipeline systems, specifically X60 SSAW (Spiral Submerged Arc Welded) pipes. This innovative technology is changing the landscape of oil pipeline construction, ensuring the safe and efficient transportation of energy resources.

X60 SSAW line pipe is known for its strength and durability, making it a top choice for oil pipeline projects. Its spiral design enhances flexibility and resistance to external pressure, which is critical to the demanding environments these pipelines operate in. As energy companies seek to optimize operations and reduce costs, the adoption of advanced piping systems such as X60 SSAW is becoming more common.

FAQS

Q1. What is X60 SSAW Linepipe?

X60 SSAW (Spiral Submerged Arc Welded) Line Pipe is a spiral steel pipe designed for oil pipeline construction. Its unique spiral welding technology improves strength and durability, making it an ideal choice for long-distance transportation of oil and gas.

Q2. Why is X60 spiral submerged arc welded line pipe the first choice for oil pipelines?

X60 SSAW line pipe is favored for its resistance to high pressure and corrosion. This ensures the reliable and safe transportation of oil and gas, which is critical in today's energy landscape.

Q3. How does your company ensure the quality of your products?

The company adheres to strict quality control measures throughout the entire production process. We utilize advanced technology and skilled personnel to ensure that each X60 spiral submerged arc welded line pipe meets international standards and customer specifications.

Q4. What are the uses of X60 SSAW line pipe?

X60 SSAW Line Pipe is primarily used in the oil and gas industry for the transportation of crude oil, natural gas and other fluids. Its versatility also allows it to be used in a variety of construction and infrastructure projects.